TB 1--1520--238--20--106

f.

Component/Parts in Stock Including War Reserves at All Levels (Depot and Others). N/A.

2.

Task/Inspection Suspense Date. Prior to next flight.

3.

4.

Summary of the Problem.

a. A number of AH--64A and AH--64D aircraft which have had tail boom improvement ECP 1315 (RSN

97A001) applied have been found to have Vertical Stabilizer Attachment Bolts shanking at the grip (non--

threaded portion of bolt). The asymmetrical stresses induced into the bolt, added to flight loads could cause

bolt to fail.

b. For manpower/downtime and funding impacts, see paragraph 12.

c.

The purpose of this TB is to ensure that the Vertical Stabilizer attachment hardware is installed cor-

rectly.

5.

End Items to be inspected. All AH--64 series aircraft.

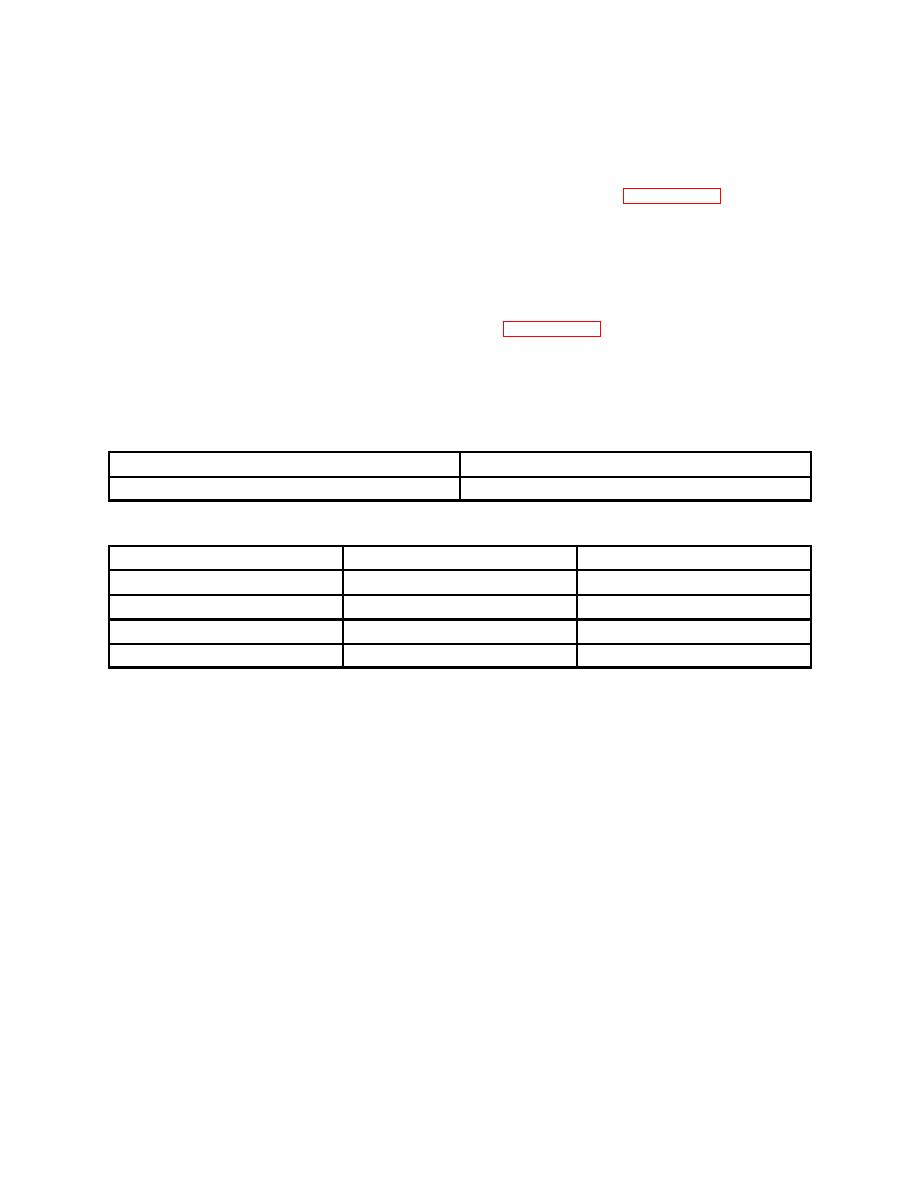

Assembly Components to be Inspected.

NOMENCLATURE

PART NUMBER

Vertical Stabilizer

7--31122600

7.

Parts to be Inspected.

NOMENCLATURE

PART NUMBER

NATIONAL STOCK NUMBER

Bolt Shear

HS 5798-9-24

5306--01--465--8474

Barrel Nut

HS 5813--9

5310--01--463--1730

Retainer

NAS 578-9B

5340--00--853--9862

Washer, Recessed

MS20002C9

5310--00--596--1712

Inspection Procedures.

NOTE

ECP 1315 has been applied to all AH--64D Longbow aircraft during the remanufacturing

process, therefore any reference to ECP1315 will not be annotated in the Historical Re-

cords of the AH--64D (i.e. all AH--64D's are affected).

a. Prior to next flight, inspect records to determine wether ECP 1315 (RSN97A001) has been applied.

If records search is inconclusive, evidence that ECP1315 has been applied is tail boom slot closure and pres-

ence of elastomeric stabilator mounts. If the ECP has been applied, inspect bolts attaching Vertical Stabilizer

to tailboom for proper installation and torque. If ECP 1315 (RSN97A001) has not been applied, the inspection

is complete.

b. If the barrel nut is visible through the retainer, check to see that the end of the bolt can be seen by

looking for the chamfer or a partial thread.

NOTE

Barrel Nut run-on torque shall be 24 inch pounds minimum.

c. If the end of bolt can be seen, retorque to assure bolt is properly torqued. Retorque only one bolt

at a time. Torque bolts to 75 inch pounds. Then torque each bolt in increments of 350 in pounds to 1350--1420

inch pounds.

2

Previous Page

Previous Page