TB 1-1520-237-20-151

(c) inspect aluminum end plates of the spherical bearing for corner and surface damage, cor-

rosion, cracks, nicks, and scratches. No cracks allowed. Surface damage may be repaired/blended out

using 400 grit abrasive cloth (P-C-451). Blend reworked area with crocus cloth (P-C-458). Polish to

0.001 to 0.002 inch below damage depth. Repair may not exceed 0.005 inch in depth and a minimum

of one part depth required between multiple damages not to exceed 20 percent of total surface area.

No blending is allowed around the 0.255 to 0.260 holes or in the spline area. Apply alodine

(MIL-C-81706) to blended aluminum surfaces.

CAUTION

Alodine, MIL-C-81706, contains a chromium compound recognized as a potential carcinogen.

Goggles, skin protection, and respiratory protection are mandatory. Extreme fire hazard if powder

is allowed to contact organic materials such as sawdust, paper, or rags.

(d) Locate the index marks (0, three places, one each on the bearing mating flanges and the

thrust bearing endplate) and align the elastomeric thrust and spherical bearings.

(e) Apply a thin, even coat of MIL-P-23377 or equivalent primer to bolts and washers. Install

the MS20002C4 washers with the countersunk side of the washer facing the bolt head.

(f) Install replacement NAS1304-6 or NAS1954-6 with washers installed through the bolt

holes while primer is wet with bolt heads facing the thrust bearing side. Install the AN960-416L washers

and MS21083N4 nuts. Torque nuts to 45 inch-pounds.

(g) Apply MIL-S-8802 Class B2 sealant to edges of bolt heads and edges of nuts and allow

to dry.

10. Supply/Parts and Disposition.

a. Parts Required. Items cited in paragraphs 6 and 7 may be required to replace defective items. The

following items which may be required when bearing is disassembled should be requisitioned as required.

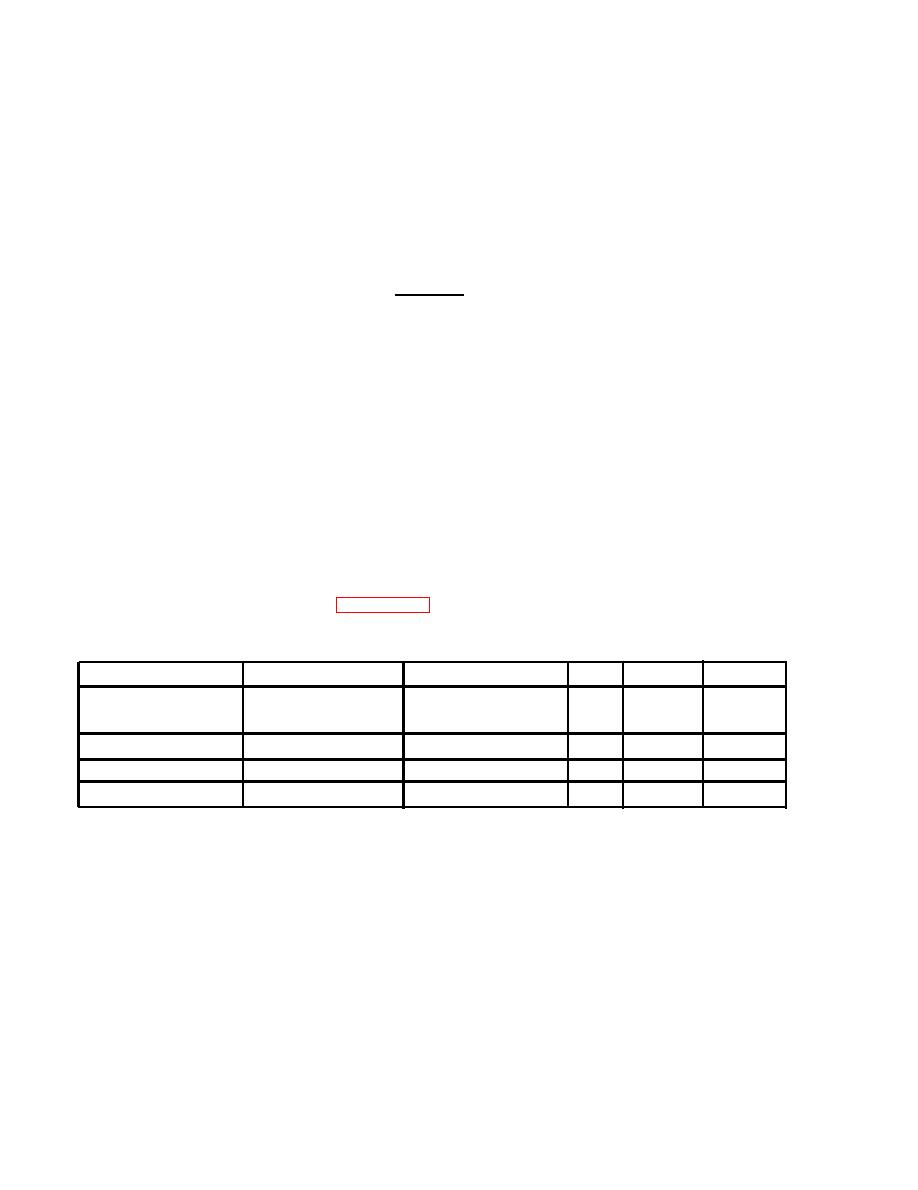

NOMENCLATURE

NSN

QTY

UI

PART NO

COST

Bolt, Shear

NAS1304-6

8

EA

0.26

8

EA

0.26

NAS1954-6

MS20002C4

Washer, Rec

8

2.56

HD

asher, Flt

AN960-416L

8

HD

0.59

MS21083N4

Nut, Self LK

8

EA

0.06

b. Requisitioning Instructions. All requirements for replacement bearings must be consolidated at the

MACOM level for OCONUS units or DMMC/installation level for CONUS units. After consolidation, requests

in the form of a memorandum, or message, shall be submitted, memorandum or message must include:

(1) Subject: Request for replacement main rotor elastomeric thrust bearings.

(2) The quantity required and whether or not the replacement bearings are for installation on air-

craft or replacement stock.

(3) DODAAC.

(4) In-The-Clear shipping address.

(5) Point of contact and phone number

(6) S/N of cr bearings to be replaced.

4

Previous Page

Previous Page