TB 1-1520-237-20-181

(2) Wholesale Stock. Upon receipt of this TB, depot commanders shall ensure inspection of all items listed in

paragraph 6. All items listed in paragraph 6. below shall be placed in conditions code " " and retagged with a

D

Test/Modification Tag/Label Material (blue color) DD Form 157611576-1. The authority block must reference inspections

required per this TB.

2. Task/Inspection Suspense Date. Within 100 flight hours/180 days whichever comes first.

3. Reporting Compliance Suspense Date. No later than 29 October 1996 per paragraph 14.a. of this TB.

4. Summary of the Problem.

a. During manufacturing of some main rotor hub assemblies, the proper edge break was not applied to the inside

edge of one of the damper bracket attachment holes. Stress risers can result from this condition, which increases the

opportunity for cracks to develop.

b. For manpower/downtime and funding impacts, see paragraph 12.

c. The purpose of this TB is to:

(1) Inspect all main rotor hub assemblies for proper edge break.

(2) NDI inspect and edge break all assemblies found deficient.

(3) Perform a NDI inspection on all main rotor hubs for cracks during the 500 hour phase inspection.

5. End Items to be Inspected. All H-60 aircraft. Serial Numbers 95-26645, 95-26650 through 95-26655 and 95-26660

and subsequent will be inspected and corrected for proper edge break by the contractor during production. However,

these hubs will require the NDI inspection at the 500 hour phase IAW paragraph 9.d.

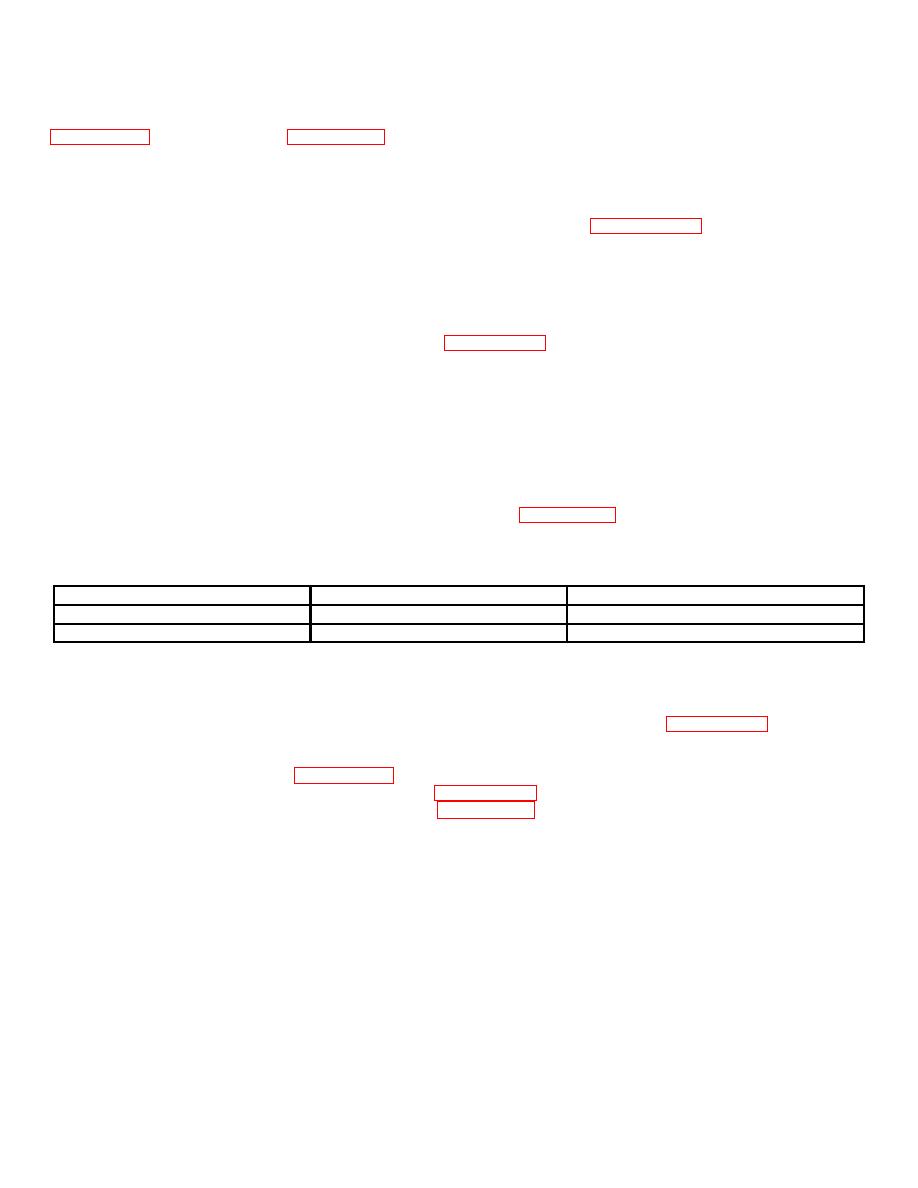

6. Assembly Components to be Inspected.

NOMENCLATURE

PART NUMBER

NATIONAL STOCK NUMBER

Main Rotor Hub Assembly

70103-08112-041

Main Rotor Hub Assembly

70103-08112-045

7. Parts to be Inspected. N/A.

8. Inspection Procedures. A visual inspection of all main rotor hub assemblies will be performed by a Sikorsky Aircraft

representative. The Sikorsky Aircraft representative will be scheduled in accordance with paragraph 9.a. The Sikorsky

representative will visually inspect all hub assemblies at the damper bracket 11 O'Clock bolt hole for proper edge break If

the edge break is found deficient on Sikorsky manufactured assemblies, a Sikorsky team will perform the required rework

and NDI inspections as described in paragraph 9.b. If the assembly was manufactured by Purdy Manufacturing, a Purdy

team will perform the required rework as described in paragraph 9.b. All hub assemblies that remain in service will

require a minimum of one NDI inspection as described in paragraph 9.d.

9. Correction Procedures.

a. One-Time Inspection for Proper Edge Break Scheduling of the one-time inspection for edge break will be

controlled by the logistical point of contact (POC). Units will be notified of the date when the inspection is scheduled for

their aircraft. No disassembly is required for the inspection. The inspection will be conducted by Sikorsky

representatives.

b. If a hub assembly is found deficient, a Sikorsky team or Purdy team will perform the necessary rework

including:

(1) Initial NDI inspection for cracks.

(2) Break sharp edge around 11 O'Clock hole.

2

Previous Page

Previous Page