TB 1-1520-237-20-212

NOTE

Temperature of the part and surrounding area must be stable and between 40 degrees F and

120 degrees F. When performing inspection at or near the minimum temperature use a dwell

time 120 minutes.

NOTE

Use a dark cloth or plastic sheet to exclude as much ambient white light from the inspection

area when doing the inspection.

(a) Spray the soluble penetrant onto a soft bristle brush or cotton swab. Throughly paint the

area to be inspected.

(b) When performing FPI at temperatures between 60-100 degrees F allow a 60 minute

dwell time. When performing FPI at temperatures from 40-60 degrees F the dwell time shall be 120 min-

utes. Re-wet the surface with penetrant if necessary during the dwell time to prevent drying of the pene-

trant on the inspection surface.

(c) A black light shall be used to examine the part surface during the removal of the pene-

trant. Verify black light intensity prior to performing the FPI. Minimum intensity shall be 1000 microwatts

per centimeter squared at 15 inches from the blub face IAW TM 1-1500-335-23.

(d) Remove penetrant IAW TM 1-1500-335-23. Apply the non-aqueous developer and

watch for any indication of cracking originating out of the hole. Continued bleedout from the insert may

mask indication of small cracks. The developer dwell time shall be 30 minutes. Using the black light, moni-

tor developer progress throughout the developer cycle.

NOTE

Excessive application of developer will mask cracks and will require complete cleaning and

reprocessing. Due to limited space, extreme care should be used when applying the devel-

oper.

(7) No cracks allowed. lf there is any indication of cracking, wipe the indication with solvent

dampened rag or cotton swab and when dry reapply developer to verify indication. Any recurring bleedout

is sufficient for rejection and correct IAW para 9. If there is no recurrence of the crack indication after specified

developer dwell time, the initial indication Is deemed not relevant.

(8) If no cracks are found, clean and re-assemble IAW normal TM procedures. Inspection is

complete. Annotate task completion on the Main Rotor Hub DA Form 2408-8-5-1 and annotate DA Form

2408-18 to schedule recurring inspections. Report completion of initial inspection IAW 14b. Reports of recur-

ring inspections are not required.

Correction Procedures.

9.

a.

Replace cracked hub immediately. Refer to paragraph 10d for disposition. Report IAW 14b.

b. A copy of this TB shall be inserted in the appropriate publications as authority to implement the in-

spection.

10. Supply/Parts and Disposition.

a. Parts Required. If the inspected assembly must be replaced, the following items will be required.

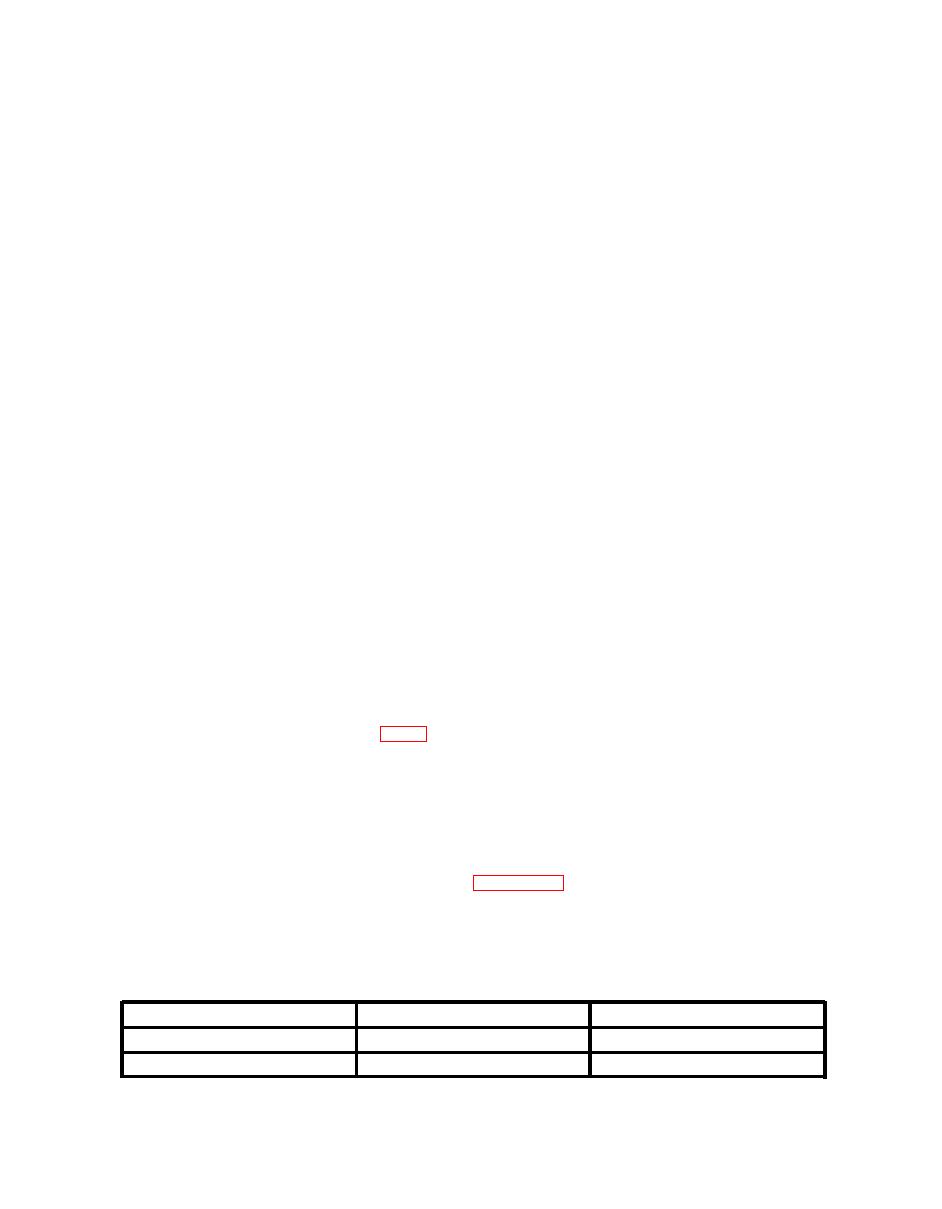

NOMENCLATURE

PART NUMBER

NATIONAL STOCK NUMBER

70103-08112-041

Hub, Rotor, Assembly

Hub, Rotor, Assembly

70103-08112-045

(MH-60K)

4

Previous Page

Previous Page