TB 1-1520-238-20-86

b. For manpower/ downtime and funding impacts, refer to paragraph 12.

c. The purpose of this TB is to direct a recurring preflight inspection of all AH-64 aircraft which have accumulated 1

750 or more flight hours and have not been modified either by application of a 2L stringer doubler (per MWO 1-1520-

238-50-32) or by closure of the slot area between Fuselage Stations (FS) 370 and 450. The inspection area bounds the

No. 2 left hand stringer between FS 409 and FS 476.

5. End Items to be inspected. Inspect all AH-64 aircraft that have accumulated 1750 or more flight hours, Serial Nos.

82-23355 and subsequent, (except those aircraft modified per MWO 1-1520-238-50-32 or by slot closure between FS

370 and FS 450).

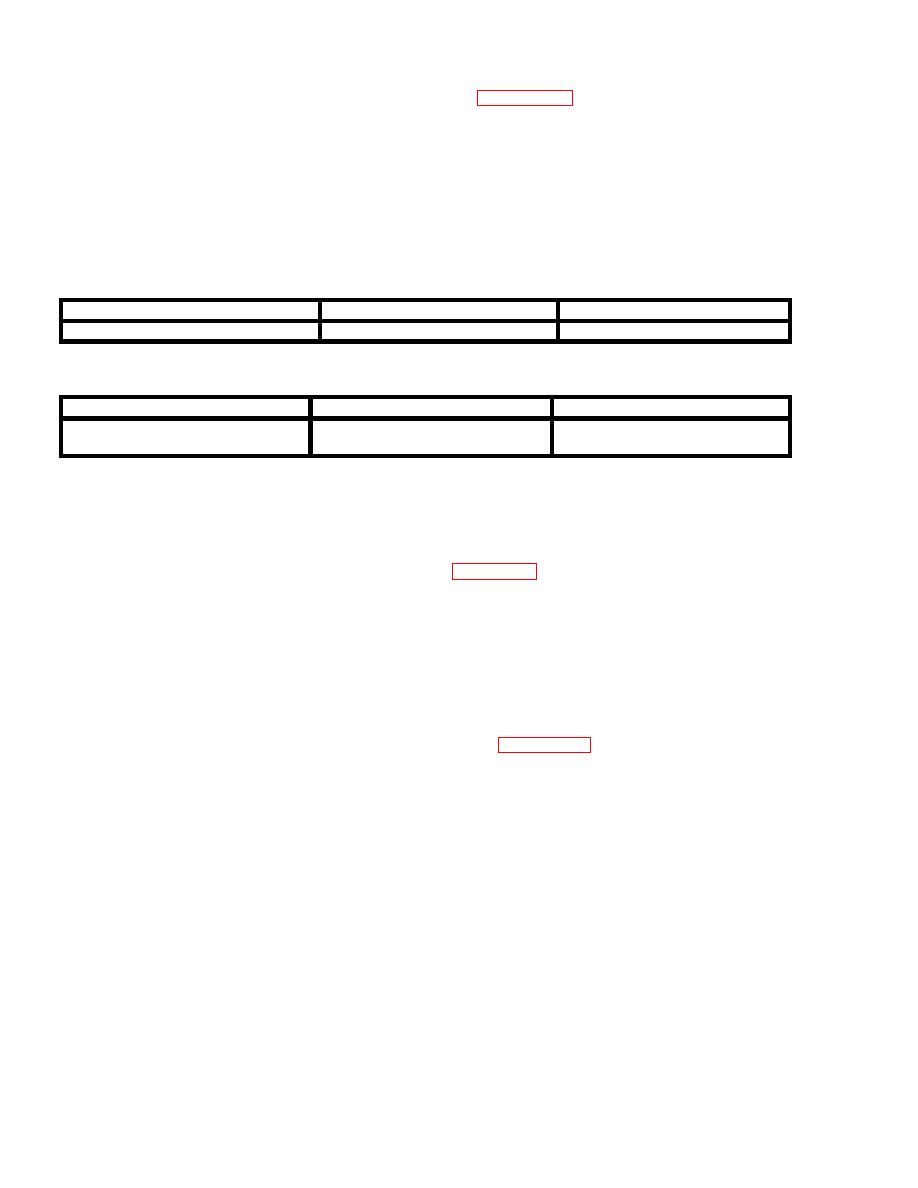

6. Assembly Components to be Inspected.

NOMENCLATURE

PART NUMBER

NATIONAL STOCK NUMBER

Skin and Stringer

7-311113512

N/A

7. Parts to be Inspected.

NOMENCLATURE

PART NUMBER

NATIONAL STOCK NUMBER

Stringer, No. 2L

7-311113803-1

N/A

Skin, Aft, Top

7-311113512-87

N/A

8. Inspection Procedures.

a. Inspect the skin surface over the No. 2L stringer area of the slot on the upper left side of the tailboom from FS

409 through FS 476 before each flight.

b. Concentrate on the skin surface over the No. 2L stringer, and inspect for working rivets or skin cracking.

c. If working rivets or skin cracking are found, refer to paragraph 9.

d. If no defects are found, the aircraft is operational. Continue to perform the recurring inspection before each

flight. The accumulated flight hours shall not exceed three (3) flight hours between inspections.

e. This recurring inspection shall be performed until a doubler strap is installed or the slot area is dosed per

USMTCOM approved procedure/personnel.

f. Mark the skin inspection area using paint stripes to facilitate the inspection. Place a paint stripe at FS 408 and

another at FS 477 on the area around the No. 2 left hand stringer.

9. Correction Procedures.

a. If skin cracks are found during the inspection (refer to paragraph 8), inspect the No. 2L stringer inside the

fuselage.

(1) Inspect the area of the stringer directly in line with the skin crack and the area three rivet rows forward

and aft of the crack.

(2) Perform a fluorescent penetrant inspection and use a 10X magnifier.

(a) If the stringer is cracked, the aircraft is non-operational until the stringer is replaced. Contact the

technical POC.

(b) If no crack is found, proceed to step 3.

(3) Perform USMTCOM approved eddy current inspection. Contact technical POC.

b. If working rivets are found, inspect the corresponding hole area in the No. 2L stringer inside the tailboom, and

check the three (3) adjacent fastener holes forward and aft.

(1) Determine if the fastener can be moved by hand.

3

Previous Page

Previous Page