TB 1-1730-229-30-03

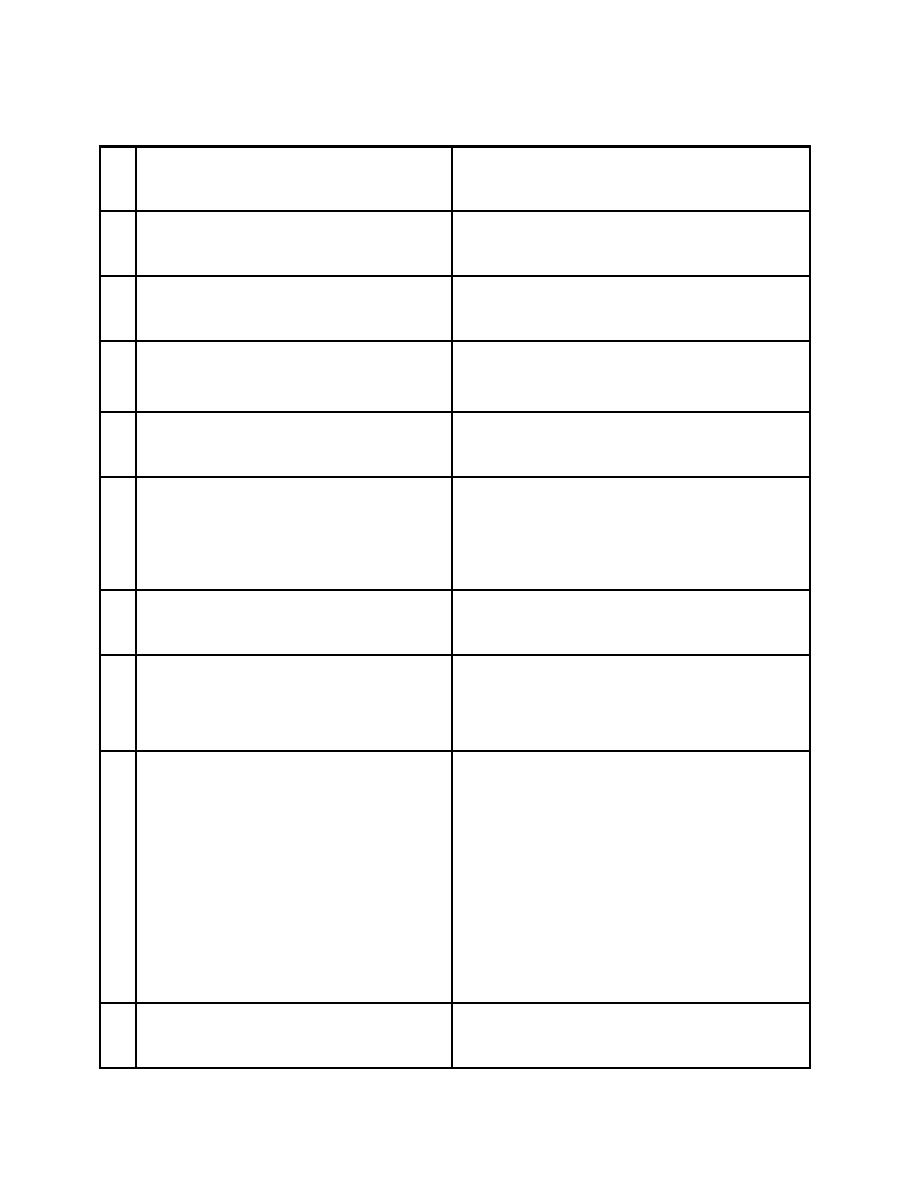

Table 1. Technical Inspection Checklist (Continued)

29

Check that all hose manifold ports and hose

ends are protected with metal dust caps or

plugs.

30

Inspect hydraulic filter housing assembly,

filter head indicator, and wiring for cracks,

damage, or leaks.

31

Inspect vent dryer desiccant canister

installation.

32

Inspect AC and DC power cables for

damage to insulation.

33

Inspect AC and DC power cables electrical

connectors for damage and freedom from

dirt and corrosion.

34

Verify that pneumatic hose clamps on

internal hose and external chafe liner are

secure, inspect hoses for correct hose type

and splits or cuts, and inspect connector

fitting for damage to locking/un-locking

devise and freedom from dirt and corrosion.

35

Verify that the AGPU pneumatic hose aircraft

coupler is secure and not damaged.

36

Inspect axles and suspension. Inspect axle

assembly for cracked or dented housing;

bent, missing or broken components; loose

or missing fasteners; broken or missing

lubrication fittings; and lubricant leaks.

37

Inspect tires and wheels for condition

(excessive wear, cuts, or foreign objects).

Each tire must have 3/16 inch or more of

tread remaining, and be in good serviceable

condition. All tires on an AGPU vehicle must

be matched to provide proper performance

and approximately equal life. Tires will not

show evidence of cupping or chunking.

Tires will not have cuts or cracks. Rubber

separation or bulges on tire sidewalls are not

acceptable. Inspect wheels for missing lug

nuts. Wheels will be free of cracks, breaks

and damaged mounting holes. Note odd rims

that do not match.

38

Inspect tow bar speed/direction control

assembly for damage and loose or missing

components, and dented housing.

14

Previous Page

Previous Page