TB 1-1730-229-30-3

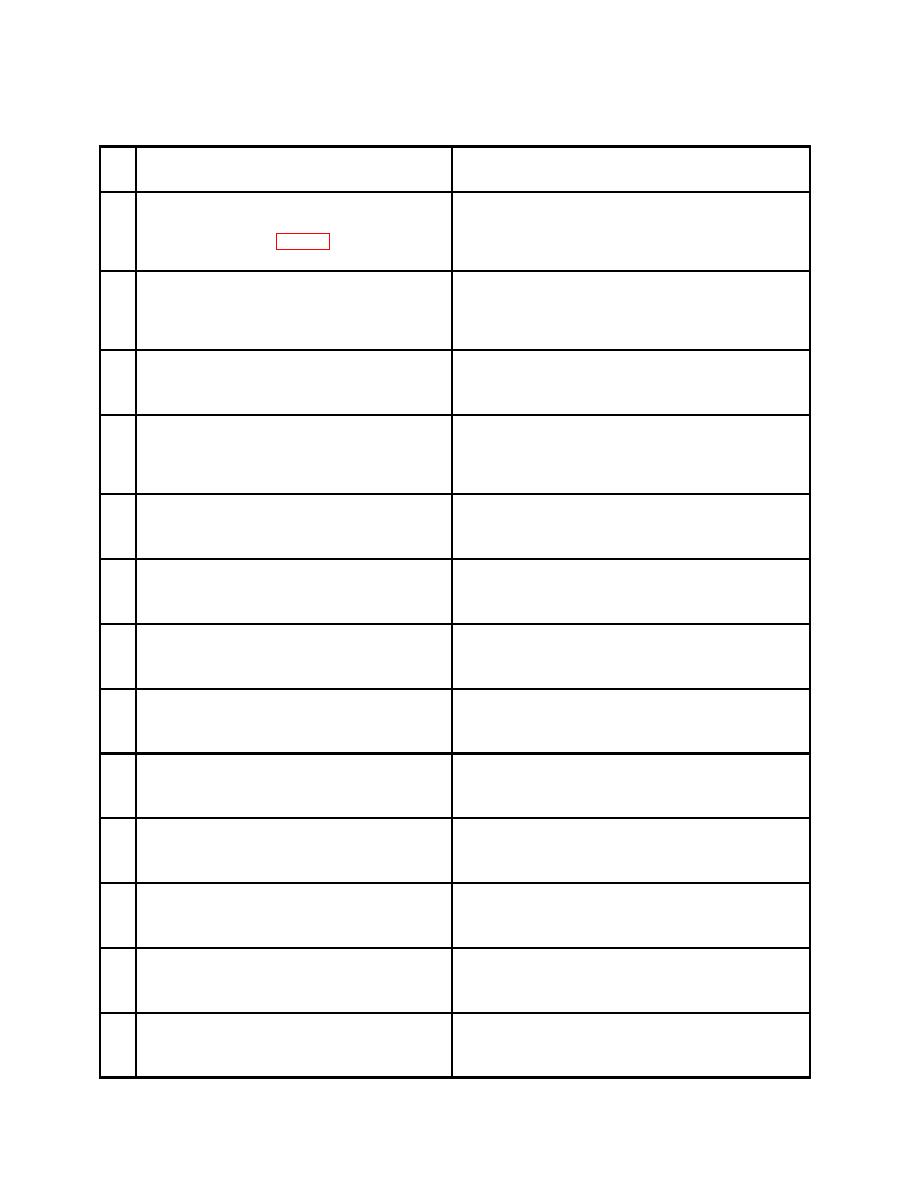

Table 1. Technical Inspection Checklist (Continued)

15

Ensure that battery cables and connectors

are in-place and not damaged.

16

Verify the battery charger selector switch on

lower tray in electrical compartment is set to

proper position (See table 2-4, TM 55-1730-

229-12).

17

Inspect lubricating oil level by examining the

sight glass on engine gear case; add oil as

required IAW LO55-1730-229-12, TM 55-

1730-229-12, and TM 55-1730-229-34.

18

Inspect interior of engine compartment for

damage, signs of fuel or oil leaks, dirt, and

corrosion.

19

Inspect air intake and ductwork assembly for

punctures, corrosion, and loose mounting

screws. Check operation of spring-loaded

bypass door by pushing in on door.

20

Verify that fuel lines are connected to fuel

control unit.

21

Verify that bolts on engine mounts are

secure and lock wired. Verify that bolts on

generator support are secure and lock wired.

22

Inspect hour meter for damage and are

securely installed.

23

Inspect starter assembly to ensure power

cables are secure.

24

Inspect hydraulic hoses for cuts, splits, or

leaks; verify hoses are securely fastened.

Inspect hydraulic pump for security, damage,

25

leaks, or loose fittings.

Ensure hydraulic reservoir is at least 3/4 full.

26

Inspect hydraulic control panel switches and

27

indicators for missing or loose parts and

corrosion.

28

Inspect reservoir gauge and thermometer

and pressure gauge for leaks or cracked

glass.

13

Previous Page

Previous Page