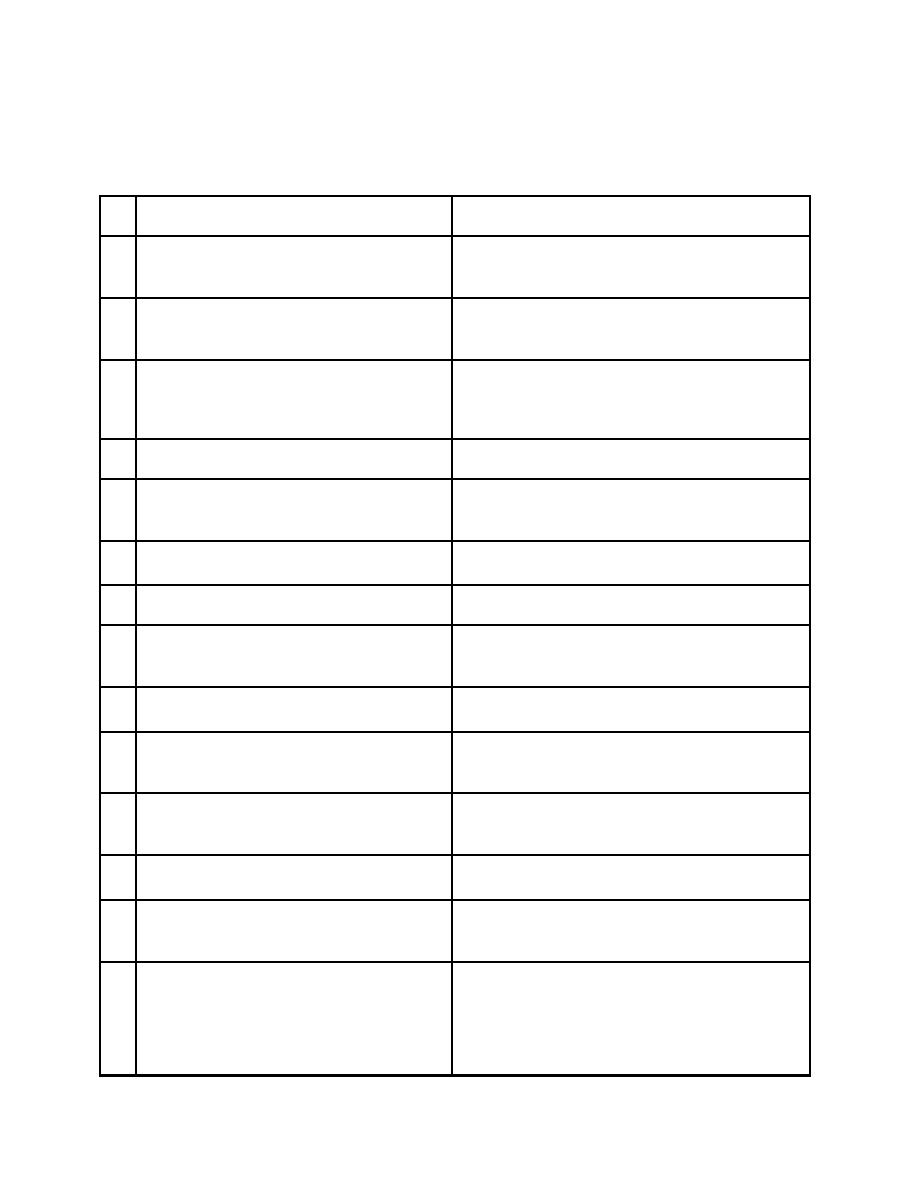

TB 1-1730-229-30-03

Technical Inspection

Condition

1

Make sure AGPU is free of tools, equipment,

fluid leaks (fuel, engine oil, and hydraulic

fluid), dirt, and corrosion.

2

Set (lower) parking brake. Disengage clutch

lever and ensure quick-release pin is

installed.

3

Make sure area above exhaust flapper is

clear of obstructions that may be ignited or

damaged by the extremely hot exhaust

gases.

4

Verify exhaust flapper operates properly.

5

On a D-Model, inspect the exhaust system

for missing/loose tape and insulation and/or

damaged components.

6

Inspect ground stud for secure mounting and

nut-retaining clip is present.

7

Verify the AGPU is properly grounded.

8

Inspect frame, covers, latches, and panels

for dents, cracks, punctures, corrosion, and

security.

9

Determine if the four lifting eyes are in place

and inspect for damage.

10

Inspect access doors for damage, and

ensure that latches and hinges operate

properly.

11

Inspect switches, circuit breakers, and

indicators for missing parts, damage, or

corrosion.

12

Inspect meters and gauges for cracked glass

or signs of corrosion.

13

Ensure that all stencils, data plates, decals,

and schematics are legible. Questionable

items shall be replaced.

14

Inspect battery compartment, battery, battery

tray and battery hold-down and guides for

damage or corrosion. If other than Optima

batteries are installed, determine whether

vent and drain tubes are in place. Determine

if battery hold-downs are tight.

12

Previous Page

Previous Page