SB 742-1

INSPECTION PROCEDURES FOR PROPELLING CHARGE CONTAINERS

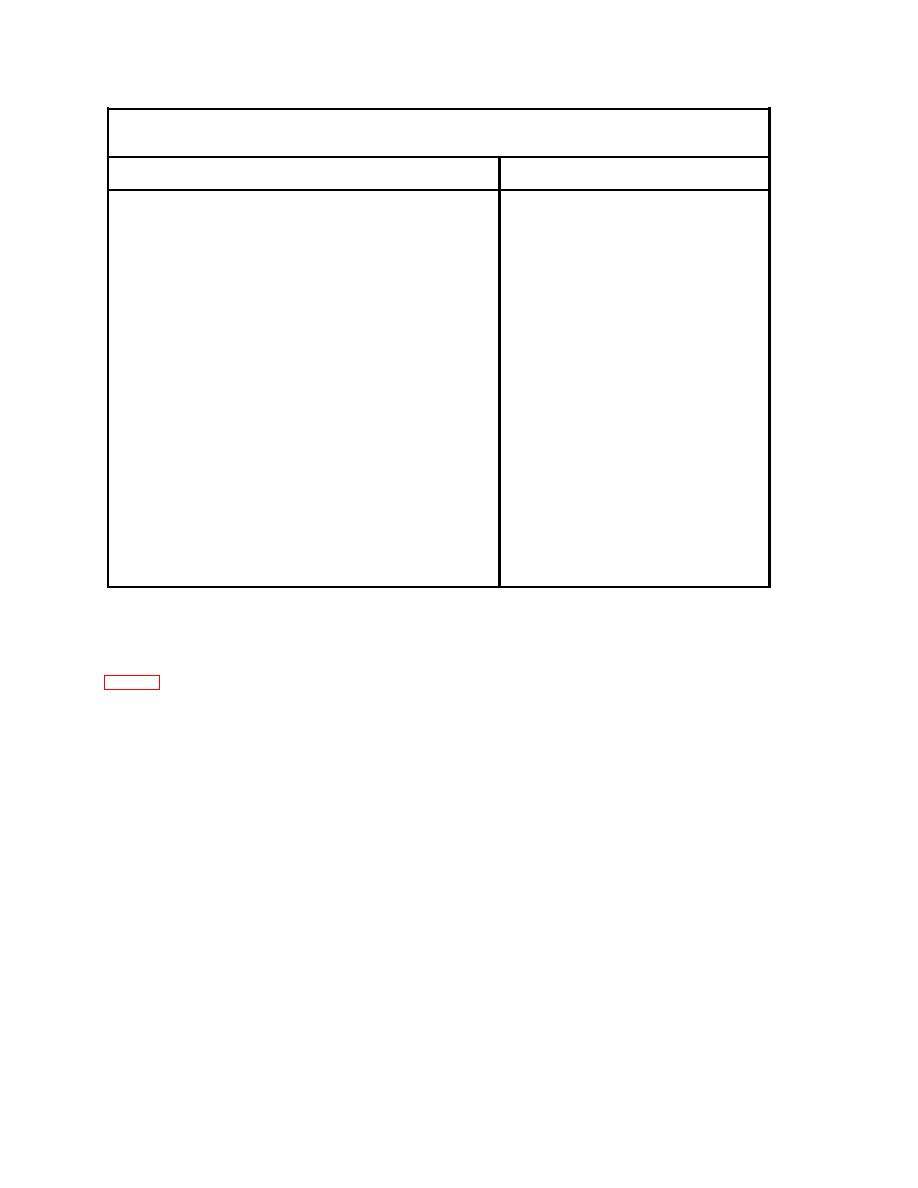

CHECKPOINT

CORRECTIVE ACTION

Replace gasket.

Metal container lid gasket missing, out of place,

damaged, or deteriorated.

Replace gasket and retest. If fails a

Failure to pass leak test.

second time, reject container.

Replace plug.

Air sampling plug missing.

Replace sampling plug/lid.

Damaged threads on air sampling plug/port.

Reject container.

Container dented precluding use; i.e.,

munition would not fit into container,

container would not seal.

Repair and renovate container to

Foreign material, rust, dust, paint chips, etc., which

serviceable standards. If not

would not allow container sealing or allow markings to

possible, reject container.

be stenciled on the container.

7-8. Reporting of leaking munitions.

b. Written and telephonic munition leaker reports must

contain, as a minimum, the information reflected below in the

a. All

occurrences

of

confirmed

positive

agent

format provided. If the prescribed format for the munition

concentrations will be telephonically reported to, addressee in

leaker report is too restrictive to convey details, provide

additional narrative.

daily telephonic updates during normal duty days will be

provided.

As a closeout action, when the positive agent

concentration no longer exists, and leaker(s) have been found

and containerized, a written leaker report will be submitted.

Previous Page

Previous Page