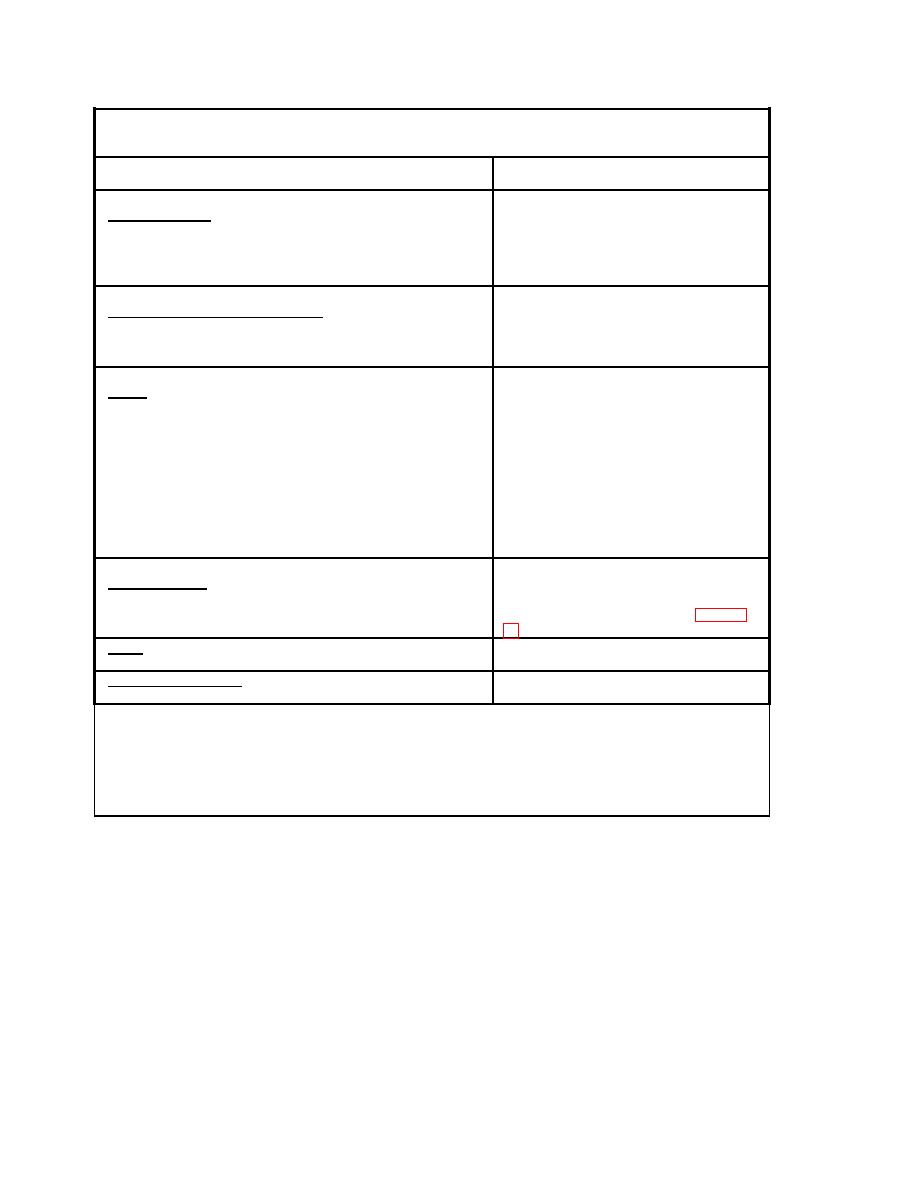

SB 742-1

SINGLE ROUND CONTAINER (SRC) INSPECTION CRITERIA (M55)

CHECKPOINT

CORRECTIVE ACTION

Container body

Reject container.

Cracks or holes.

Reject container.

Dents which preclude use.

None required.

Dents which do not preclude use.

Reject container.

Missing or damaged components.

Sealing flange machined surface

Reject container.

Scratches which would prevent proper sealing.

Clean and apply rust preventive.*

Foreign material, rust, dust, paint chips, etc.

Reject container.

Flange bolt hole threads damaged.

Cover

Reject container.

Cracks or holes.

Reject container.

Missing or damaged component.

Attempt to find matching S/N. If not

Serial number (S/N) does not match container body

possible, perform leak test.

(when applicable).

Apply Teflon sealant (tape or liquid),

Loose inspection plug.

torque 25ft-lbs min.

Reject container.

Scratches in sealing surface/groove.

Clean and apply rust preventative.*

Foreign matter, rust, etc., in seal groove.

Container Seal

Destroy seal. Request replacement

Teflon seals: Flat spots ,irregularities, deformation, or

from NICP (the addressee at para 1-

scratches. O-rings: Cuts, irregularities, hardness, or

5d(7).

deformation.

Bolts

Damaged bolt or threads.

Replace bolt.

Container Assembly

Fails Leak Test.

Reject container.**

*Leak test container upon completion of maintenance. If the rust cannot be removed with no

coarser than fine grade steel wool and a soft rag, or there are pits or rough surfaces caused by the

rust, reject the container(s).

**After initial failure, retest with a new Teflon seal or o-ring. If failure occurs a second time, reject

container.

Previous Page

Previous Page