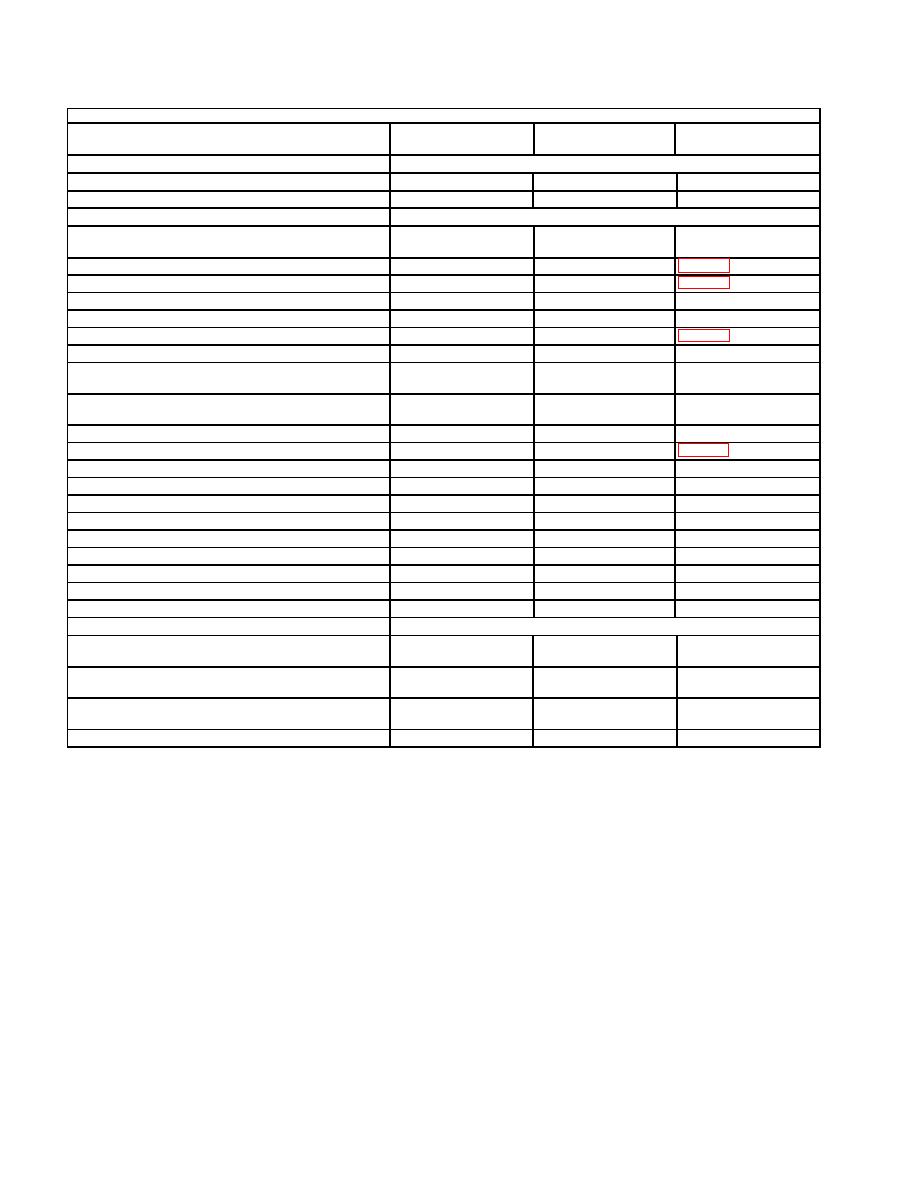

SB 742-1

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Evidence of composition B leakage

M712

Visual

b. Cracked or deeply gouged obturator

M712

Visual

2. Major:

a. Aft closure damaged to extent that it would prevent

M712

Visual

engagement of extractor

b. Missing or loose splice screws

M712

Visual

c. Loose or missing access cover

M712

Visual

d. Broken, cracked, or missing projectile ogive

M712

Visual

e. Crack or dent in any part of projectile body

M712

Visual

f. Wings extended

M712

Visual

g. Fins are loose, broken, or not in retracted position

M712

Visual

h. Water droplets condensed or fogged on interior surface of

M712

Visual

nose cone

i. Window portion of projectile ogive (nose cone) severely

M712

Visual

scratched or gouged

j. Dirt, debris, or foreign objects in wing or fin slots

M712

Visual

k. Dials on code or time switches missing, broken, or illegible

All

Visual

l. Excessive rust or pitting of bourrelet

All

Visual

m. Switch bracket broken or damaged

All

Visual

n. Cracked or deeply gouged obturator

M823

Visual

o. Missing plastic inserts (preload tabs)

All

Visual

p. Internal pressure pads missing, damaged or deteriorated

M712 Cntr

Visual

q. Cradle pads missing, loose or damaged

All Cntrs

Visual

r. Stitching loose or missing

All Cntrs

Visual

s. Straps ripped or broken

All Cntrs

Visual

t. Damaged, leaking or missing gasket

M712 Cntr

Visual

3. Minor:

a. Abrasions or smudges on window portion (nose cone) of

M712

Visual

projectile ogive

b. Water droplets on or fogging interior surface of projectile

M823

Visual

ogive (nose cone)

c. Window portion of projectile ogive (nose cone) abraded

M823

Visual

smudged, scratched or gouged

d. Dirt, debris or foreign objects in wing or fin slots

M823

Visual

d. Wings extended indicate squib has been fired.

e. Switches must rotate freely when firing codes are being

a. Humidity indicator.

set into projectile.

(1) If 40-percent sector on the humidity indicator is

f. Decals are no longer required on Copperhead

not blue for M712, desiccant will be changed according to TM

containers. However, container top and bottom are a matched

9-1300-251-34.

set, identified by serial numbers and should be assembled as

(2) The M823 training projectile container should not one unit. Mismatched top and bottom may prevent container

contain desiccant. If present, desiccant should be removed from retaining seal against humidity. Serial number may be

during IRI.

The humidity indicator card will be marked found on a decal or marked with stencil ink. If decal is peeled

"Dummy" and placed in humidity indicator unit.

off, replace with stencil. If both top and bottom are missing or

b. The splice screws should be finger tight and at or below unidentifiable, stencil both top and bottom with prefix "CNTR"

followed by projectile serial number.

flush with the projectile surface.

c. Access cover missing; screw on cover loose and cannot

be made finger tight by hand turning. Screws must be at or

below flush with the cover surface.

Previous Page

Previous Page