SB 742-1

be used to fight a fire involving HC munitions if a large amount

(3) Prior to removing the grenade from the fiber con-

of water relative to the item is available.

tainer, observe the fuze safety pin. If it is missing, do not

remove the grenade from the fiber container. If both legs of the

d. In high concentrations or on prolonged exposures, HC pin are straight or if one leg is straight and the other is bent to

smoke irritates the nose and throat and may be quite an angle less than 45 degrees, bend each leg 90 degrees in

dangerous when inhaled.

Personnel exposed to any opposite directions.

concentration of HC smoke shall wear respiratory protection.

g. If the grenade is upside down in the fiber container

e. The pin of the M201A1 fuze used on AN-M8 HC; (fuze not visible), or if any of the above discrepancies are noted,

AN-M14 Incendiary; M83 TA Smoke, and M18 smoke grenades it should remain inside the container and action taken to

can be inadvertently pulled during processing; i.e., handling, dispose of it safely.

temporary storage in boxes, at the production plant. This can

occur when grenades, which are not in the fiber container, are

h. Grenades should never be lifted or handled by the

placed in boxes and the lever on one grenade catches in the safety pin pull ring.

ring of the pin of an adjacent grenade and either pulls or

The potential for the pin to be P-3. Testing and equipment requirements. Not applicable.

partially pulls the pin.

inadvertently pulled is significant up to the point when the P-4. Inspection category and sampling plan.

grenade is placed in its fiber container. When the grenade is in

a. Inspection Category Y; Periodic inspection interval --

its fiber container, there is almost no possibility of the pin

three years.

being inadvertently pulled.

b. Sampling plan for inspection is according to chapter 2.

f. To preclude fuze pins from being inadvertently pulled,

users are cautioned to comply with the following procedures:

c. Inspection criteria for fuzes are contained in Appendix

(1) Retain the grenades in fiber container until they T.

are to be used/inspected.

d. Item will be inspected and classified according to

(2) Always store and transport the grenades in the chapter 2 and table P-1.

fiber container.

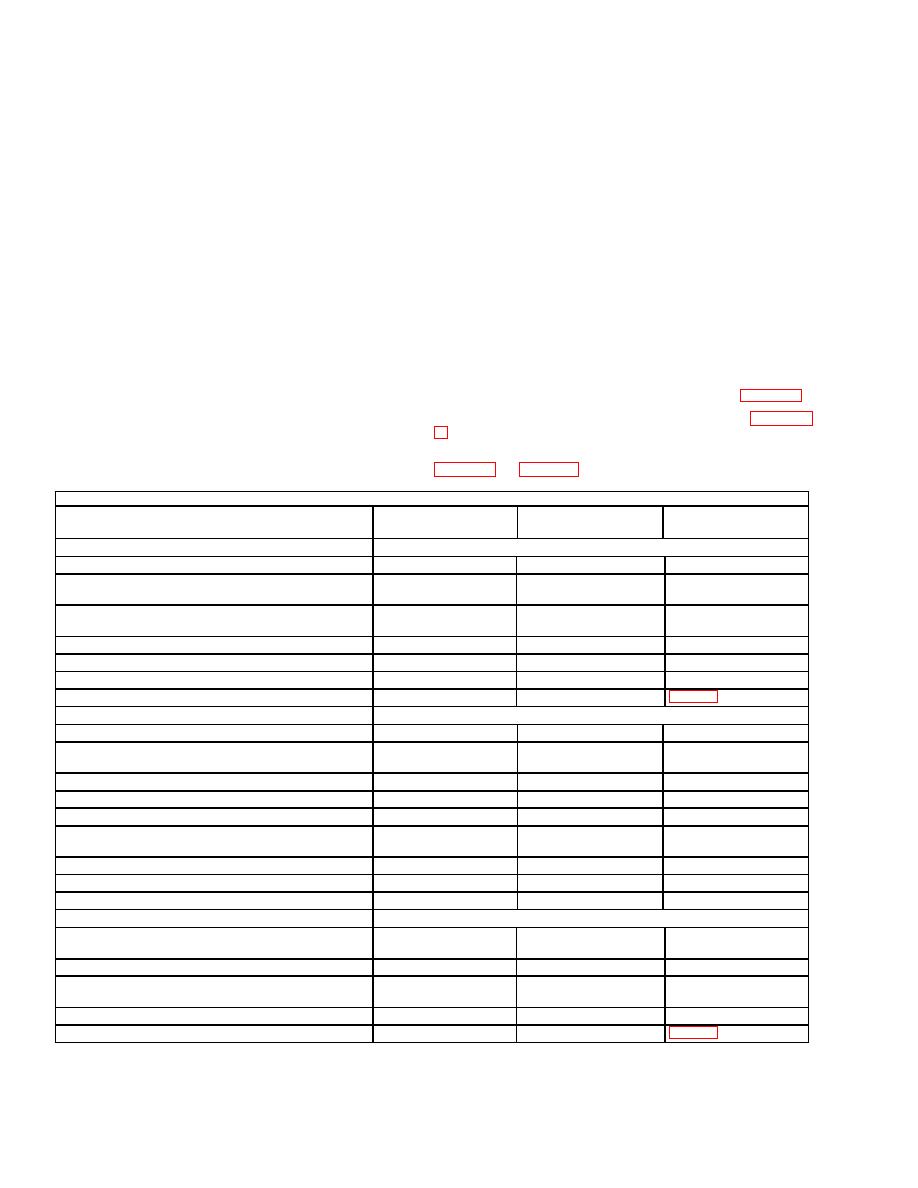

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Unauthorized fuze installed

All

Visual

b. Safety pin missing, or insecurely assembled to the extent

All

Visual

that it endangers the user

c. Grenades mixed within lot which can result in hazardous

All

Visual

or unsafe conditions for persons using or maintaining items

d. Marking misleading as to color of smoke

M18

Visual

e. Evidence of leakage

M15, M34

Visual

f. Grenade packed upside down

M15, M34

Visual

g. Emission holes missing

AN-M8, AN-M14, M48

Visual/Manual

2. Major:

a. Split seams or swollen body

All

Visual

b. Tape missing, loose, or does not completely cover

All

Visual

emission hole

c. Fuze loose; not in full 360 degree contact with gasket

All

Visual

d. Grenade contents leaking

AN-M8, M18

Visual

e. Marking incorrect

All

Visual

f. Rust or corrosion to the extent that grenade cannot be used

All

Visual

as intended

g. Grenade cannot be removed from container

All

Visual

h. Safety latch missing

M48

Visual

i. Grenade packed upside down

AN-M8, M14, M18, M48

Visual

3. Minor:

a. Marking incomplete or illegible but type of grenade and

All

Visual

lot number are identifiable

b. Minor rust/corrosion

All

Visual

c. Layers of flaked rust which, when removed, leave pitting

All

Visual

that will not affect functioning

d. Inadequate paint coverage

All

Visual

e. Grenade slurry mixture loose

M18

Visual/Manual

Previous Page

Previous Page