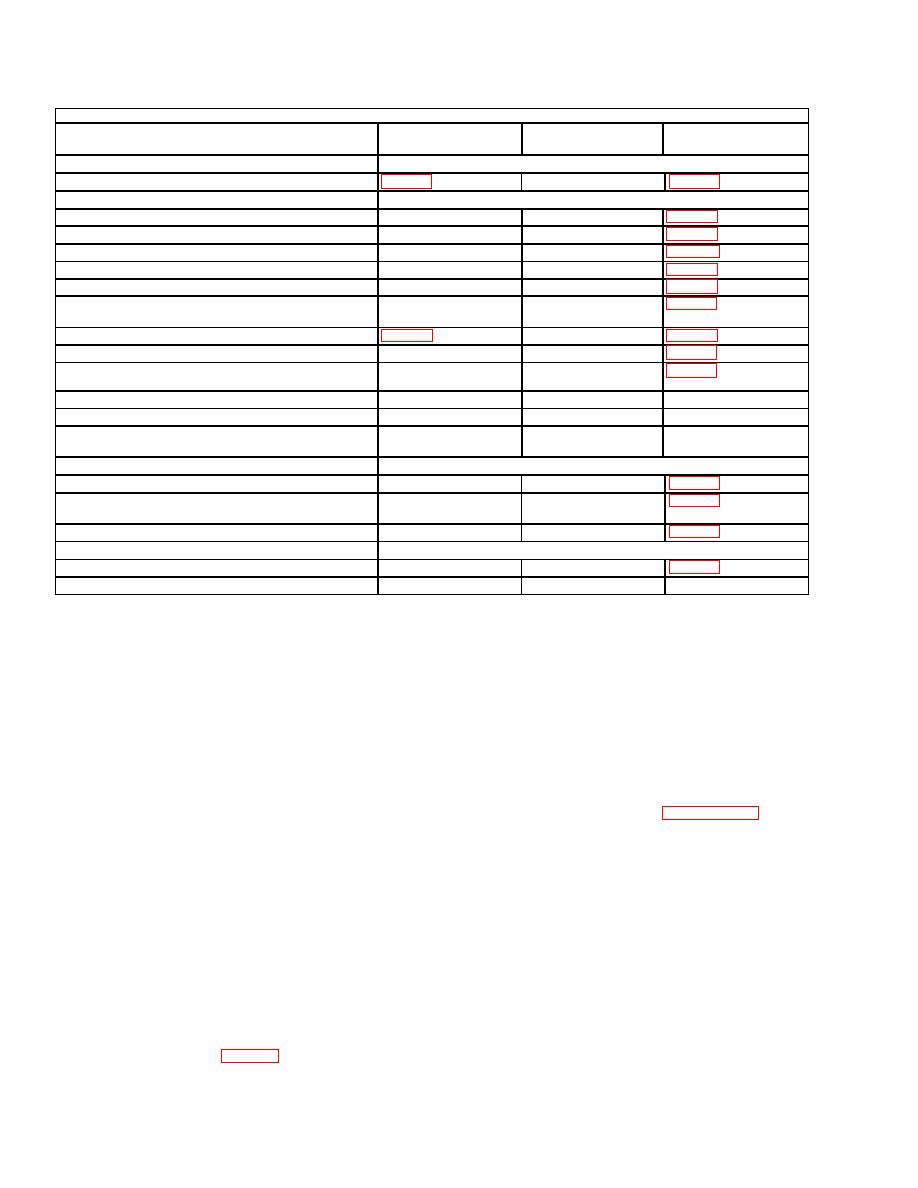

SB 742-1

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Corrosion on base

Visual

2. Major:

a. Excessive base gap

All

Gage

b. Lifting plug wrong type (not fusible)

Visual

All

c. Diameter of bourrelet greater than maximum allowed

All

Gage

d. Fiberglass wrapping damaged or loose

All

Visual/Gage

e. Loose ogive at ogive and body joint

All

Manual

f. Diamond or triangle marking missing, incorrect or

All

Visual

unidentifiable

g. Corrosion on base (old style base)

Visual

h. Corrosion on ogive

All

Visual

i. Obturator missing or damaged

All

Visual

N-6h

j. Lifting plug missing or damaged

All

Visual

k. Corrosion on fuze well threads

All

Visual

l. Expulsion Charge, not removable, or torn allowing

All

Visual

propellant leakage

3. Minor

a. Rotating band damaged

All

Visual

b. Protective coating with bare areas exceeding - inch

All

Visual

square

c. Rust in base and body gap

All

Visual/Gage

4. Incidental:

a. Corrosion on base (new style base)

All

Visual

b. Expulsion charge cup loose or removable by hand

All

Manual

tagged and identified in

storage

pending

receipt

of

disposition instructions.

a. The gap between base and body interface will be

gaged with a blade type feeler gage as follows:

(5) Sealant was used to fill base/body gap for later

production and base replacement using black bases.

(1) M483A1 projectile. Base gap criteria varies

Projectiles with sealant in this gap will not be gaged.

with drawing revision under which projectile was

assembled. Projectiles manufactured according to drawing

b. Fusible plug is painted yellow for identification

9215220, revision K, or subsequent revisions, require base

purposes.

gap not to exceed 0.003-inch.

Projectiles assembled

c. Projectiles that fail to ring gage will be measured

according to drawing revisions prior to revision K require

with a micrometer to determine if the diameter is within

base not to exceed 0.010 inch. Round will be rejected if

tolerance at all points. Take micrometer readings 90

appropriate thickness feeler gage enters gap more than

degrees apart in areas which fail to ring gage, then rotate

0.060-inch depth (approximately 1/16th-inch) for 360

micrometer completely around circumference of projectile

degrees, or for 0.125-inch depth (approximately 1/8th

to determine if diameter is within 6.0900 - 6.0984 inches at

inch) in one continuous 45-degree arc along base and body

all points. Reports submitted per paragraph 2-8g of this

joint.

supply bulletin will include micrometer readings.

(2) M692 and M731 projectiles. Reject round if a

d. Fiberglass wrap damage criteria is as follows:

0.005-inch feeler gage enters gap for more than 0.060-inch

depth for more than 180 degrees continuous arc along base

(1) Missing olive drab (OD) paint on fiberglass is

and body joint.

not a cause for rejection. Projectiles having paint missing

on portions of the fiberglass wrap (i.e., due to rubbing)

(3) M718 and M741 projectiles. Reject round if a

shall be touched up with OD paint. (Color No. 34088, MIL-

0.023-inch feeler gage enters gap for more than 0.060-inch

E-52891).

depth for more than 180 degrees continuous arc along base

and body joint.

(2) Projectiles having longitudinal gouges greater

than one inch in length and a full length depth of 0.100-

(4) All projectiles. Accept or reject criteria will be

inch or more shall be rejected. Other longitudinal gouges

0 and 1 respectively. Occurrence of one defective sample

shall have loose strands trimmed and be touched up with

will require the lot to be locally suspended from issue and

OD paint.

use. Lot should be scheduled for 100-percent screening for

excessive base gap. Details (including actual gap and

(3) Projectiles having loose strand(s) regardless of

circumferential

measurements)

will

be

reported

circumferential length resulting in a depth of less than

immediately to the office in para 1-5d(1). Rejects are to be

.0625-inch and not exceeding .500-inch longitudinal width

Previous Page

Previous Page