SB 742-1

(e) Linked ammunition consisting of one

the local lot number.

Ammunition Data Cards are not

component type and lot number will bear the lot number

required for these lots.

of the component lot, and an "L" will be used in the lot

(8) CONUS posts, camps or stations without

number to indicate functional pack. In some cases SAA

adequate personnel and facilities to perform inspection

will qualify for two identifier codes in place of a hyphen in

and processing of SAA will report through command

the lot number (reference MIL-STD-1168A). In those cases

channels to JMC according to DA PAM 738-750 for

where the functional pack identifier "L" conflicts with

disposition.

another identifier code, the "L" will be dropped and the

other code will be used.

d. Repack of small caliber ammunition. The following

criteria is to be used when repacking stocks of

(f) Dummy small arms ammunition.

ammunition

through

caliber

.50

to

different

1 Inspect dummy cartridges for such

configurations:

defects as damaged extractor groove/rim, damage which

(1) All lots must be certified for use in the may preclude use, corrosion, and loose bullets.

weapon(s) for which they are being repackaged.

2 Dummy cartridges with defects other

Certification for each lot will be obtained by furnishing a

list of component lots to the office in para 1-5d(1). than those specified above will be considered serviceable

Request for lot certification will indicate date repack is to as long as their intended purpose is unimpaired and they

start, designate the NSN to which ammunition will be can be identified as dummy.

repacked, and must be received by JMC at least three

e. SAWS ammunition (5.56-mm cartridge, models

months before the operation is scheduled to begin. Lots

not certified for use in weapons for which repack is being M855 and M856) not fully seated in metallic link belts or

accomplished will require testing. Tests will be arranged with incidental dents on cartridge case shoulder should

by the office in para 1-5d(1) upon request. Cost of tests not be rejected.

Such conditions do not affect

serviceability of ammunition.

must be borne by the requesting facility.

f. Load requirements for stockpile pull-testing of

(2) Serviceability criteria.

various SAA metal linked ammunition.

(a) Ammunition

will meet the

visual

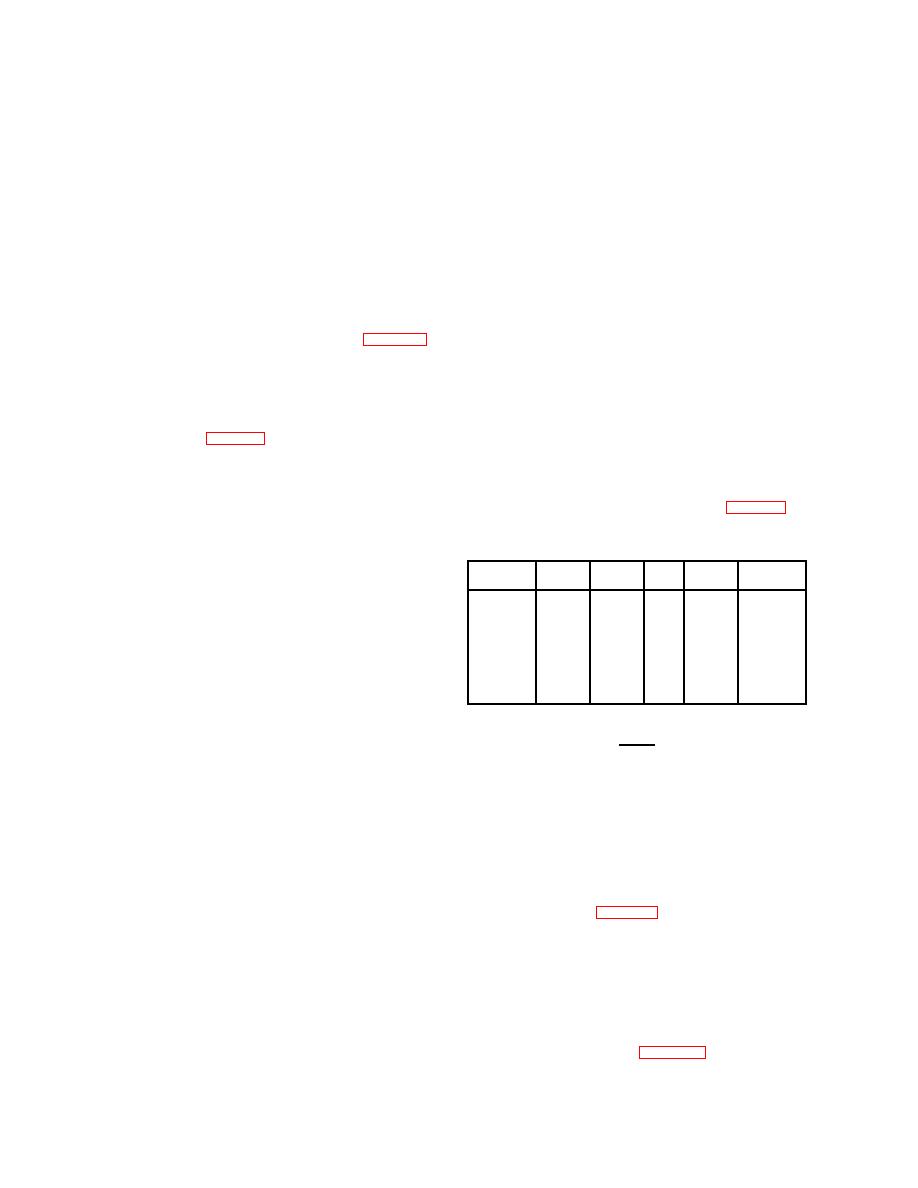

(1) The load requirements listed in table E-4 will

inspection criteria specified by the appropriate Military

apply.

Standard.

(b) Restricted or suspended ammunition will

not be used in repack operations without specific

Type

#Belt

#Link

#Ct

L Tension

authorization or instructions from the commodity

s

s

gs

oad

Time

command.

5.56mm

10

6

6

19

30 sec

7.62mm

10

25

25

lbs.

30 sec

(c) Tracer lots will have more than one-half

Cal .30

10

25

25

25

30 sec

of the trace test interval remaining.

Cal .50

10

25

25

lbs.

30 sec

(3) Lot formation criteria.

25

lbs.

(a) Functional

lots

must

meet

the

80

requirements

of

appropriate

military

standards,

lbs.

specifications and drawings. The latest revision must be

used unless otherwise directed by the commodity

command. Small caliber ammunition assembled in metal

NOTE

link belts will be tested and inspected 100-percent

according to the appropriate portion of MIL-STD-644,

Inner pack and item samples must be selected

paragraph 5.1.6.

from a minimum of ten outer packs. Additional

outer packs must be inspected at either the

(b) No more than one lot of each component

inspection or storage location(s) to make a total

will be used in a functional lot.

sample size of twenty. Pull test does not apply

to caliber .50 M15A2.

(c) Functional lots will consist of a minimum

of 30,000 rounds, unless otherwise specified by the

(2) A belt consisting of the appropriate number of

commodity command. The maximum lot size will be

links and cartridges shall be capable of withstanding the

controlled by the size of the major component (Ball, AP,

appropriate tensile load without separation. Load shall be

API, etc.).

applied at a uniform rate and belt shall remain under

(d) When directed by the commodity tension as specified in Table E-4.

command, hybrid lots may be authorized. In such cases,

g. Classification of primer defects.

up to five major component lots and two minor component

(tracer) lots may be used so long as each component

(1) Visual standards for primer defects are

displays the head stamp from one manufacture (i.e., all contained in MIL-STD-636. The purpose of the standard

ball, all AP, all tracer, etc., have the same manufacturer). is to provide a standard basis for inspection of small arms

Year of manufacture may be disregarded. If two tracer ammunition at various small arms manufacturing

lots are used, there must not be a variance of over facilities.

10-percent in any element of their tracer test (satisfactory,

(2) Defect classification of special in MIL-STD-

blind, specification trace) results. Hybrid lots will not

636 is for new production. Table E-3 will be used for

exceed 250,000 rounds.

classification of primer defect criteria.

Previous Page

Previous Page