SB 742-1

CARTRIDGE, 60-MM MORTAR

Items will be inspected and classified according to the

appropriate paragraphs of this supply bulletin and table F-2.

a. FSC: 1310.

a. All models with fuzes requiring safety wires.

b. Ammunition type: Cartridge, 60-mm mortar. Includes

the M49-series (HE), M50-series (TP), M69 (training), M83-

b. All models with M65 series fuze.

series illuminating), M302-series (WP), M720 (HE), and M888

(HE) models.

c. All applicable fuze models.

c. 60-mm cartridges are fin-stabilized rounds fired from

d. Profile and alignment gage.

Gage if visually

smooth bore weapons.

A complete round consists of a questionable.

projectile, fin assembly, ignition cartridge, primer, propelling

e. Place the damaged charge on a M27 fin, oriented so that

charge, and a fuze (the M69 trainer does not have a fuze). For

a complete description of these rounds, see TM 43-0001-28 the propellant rests against the damaged surface. Vigorously

shake the fin and charge three times. If any propellant is

and the drawing for the particular round.

spilled the damaged charge must be classified as a critical

defect. If no propellant is spilled the damaged charge will be

classed as a major defect.

No unique safety precautions are applicable to this item.

f. Ignition cartridge must be assembled with red end next

to the primers. (Dwg 9207925 and 9220383).

a. All IRI samples will be gaged using a profile and

g. Normally done only during initial receipt inspection as

alignment gage. Gaging is not normally required during PI, RI, stated in paragraph F-3a.

or UBLI. Gaging, during these inspections (other than IRI),

should be limited to individual rounds having visual evidence

h. When a component is damaged, or incorrectly

of damage or other conditions that may preclude loading and assembled, so as to affect the functioning or reliability of the

firing.

Unless the rounds requiring gaging are truly round, it will be classified as a defect.

representative of the lot being inspected, they should be

i. Discoloration of propelling charge containers is a result

disregarded in evaluating the lot.

of high humidity and temperature in storage. Color change is

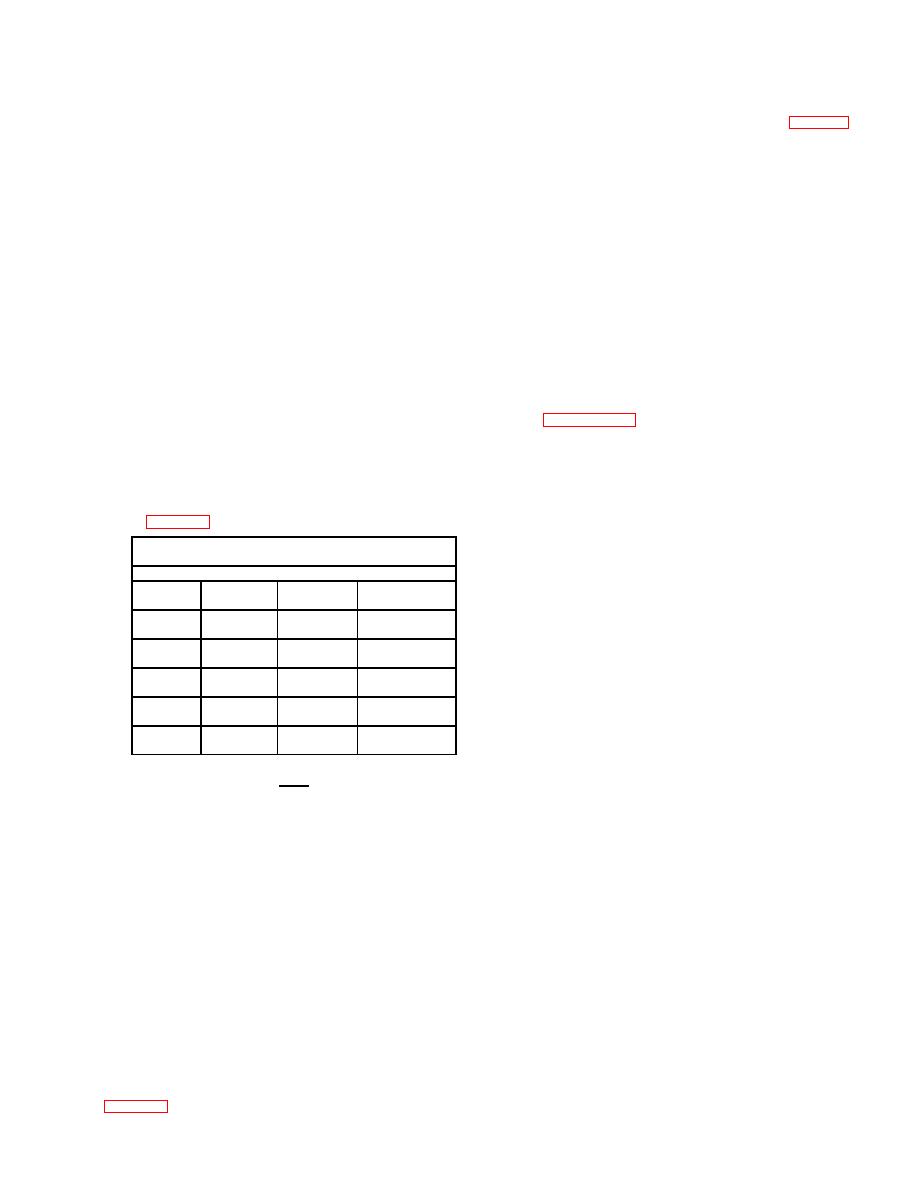

b. Table F-1 identifies test and measurement equipment.

from normal light yellow to dark yellow to light green

progressing to darker shades of green.

Splotches of

discoloration rather than a uniform transition of entire charge

.

container evidences change. When discoloration is present

Gage, profile and alignment

inspections should focus on:

Drawing

NSN

Preferred

Application

(1) Possible residue buildup on the portion of the fin

Gage

which is adjacent to the propellant containers.

7256348

5220-00-

YES

All models

305-6030

(2) Deterioration of polyurethane foam lining of the

5539280

5220-00-

NO

All models

propellant charge supports. Breakdown of this foam leaves

395-4450

complete

residue on the charge containers.

7256419

5220-00-

NO

Short rounds

(3) Cartridges are to be considered serviceable if

395-4457

only

discolored propellant containers are hard, intact and buildup

6518134

5220-00-

NO

Short rounds

does not cover ignition flash holes. Cartridges exhibiting these

395-4423

only

conditions or with foam adhering to the propellant containers

7258360 5220-00-

NO

Short rounds

are to be assigned condition code C for priority of issue.

395-4466

only

Note

Non-preferred gages will not be requisitioned or

purchased but may be used if on-hand and

serviceable

a. Inspection category.

(1) Category V: 6 years (includes jungle pack HE, WP

and TP).

(2) Category W: 5 years (includes inert items and

jungle packed illuminating cartridges).

(3) Category X: 4 years (includes HE, WP and TP not

in jungle pack).

(4) Category Y:

3

years

(includes

illuminating

cartridges not in jungle pack).

(5) Inspection interval is to be reduced to 2 years for

cartridge lots assigned condition code C due to discolored

propellant.

b. The sampling plan for inspection is according to

Previous Page

Previous Page