SB 742-1

f. If stuck expelling charges exhibit cracks with D-27. Rocket,

66mm

Incendiary,

M74,

TPA

exposed contents and/or moisture, they are to be treated (1340-H110)

as major defects, the lot condition coded accordingly, and

a. Evidence of grayish/white residue on round/

reported in accordance DA Pam 738-750.

warhead could in fact be an oxidation product from the

g. Loose components, evidenced by rattle inside the triethyl aluminum, but could also be residue from

projectile ogive during handling, is not a defect or a safety excessive epoxy sealant used to secure fill plug.

problem. Rattle is caused by looseness of spacers inserted

b. If grayish/white residue is found on warhead,

in base of projectiles during loading and packing to assure

perform the following test:

a tight pack.

Projectiles exhibiting this rattle are

considered acceptable if otherwise serviceable.

Warning

D-25. Projectile,

155MM,

M825

Series

Defect

Hydrochloric acid is corrosive and should be

Classification

handled with care. If acid contacts skin, it

should be immediately flushed with water

a. Projectile, 155MM, M825/M825A1 WP (1320-D528)

and/or sodium bicarbonate solution (baking

with missing or damaged obturating bands can cause a

soda and water).

critically short round.

Test solution is hydrochloric acid. Dilute concentrated

A missing or damaged band evidencing a crack, cut or

hydrochloric acid (commercial muriatic acid or

gouge extending across entire width of band is to

12n laboratory acid) with an equal volume of

be classified as a critical defect.

water to give approximately 6n hydrochloric acid.

A "loose" obturator band is a critical defect if the band

Test solution should be poured into a dropper

will not remain in the groove. If band can be

bottle for use. This solution should be obtained

manually removed for groove, but can also be

from the medical officer, post hospital, laboratory

"snapped" back into groove, round is to be

or pharmacy.

considered serviceable.

Neutralizing/cleanup solution is a saturated solution of

Circumferential movement of obturator is not classified

sodium bicarbonate (baking soda) in water. Mix

as a defect.

the baking soda into a container of water until no

more dissolves.

b. Canister component lot numbers have been

stenciled on each projectile. This is not a defect but

Place 2-4 drops of acid solution directly on powder on

makes end item lot identification more difficult. Item

warhead or on powder scraped off warhead into a

drawings provide correct location for projectile lot number.

plastic or ceramic container (dish). If residue is

oxidation product from triethyl aluminum, it

c. Corrosion on aluminum portion of M825 projectile

should dissolve away.

Follow procedures of

base is a critical defect.

Procedure for conduct of

reference directing clip be submerged in oil, and

inspection and defect classification criteria is same as that

report as a critical defect.

for M483A1 projectiles with old type "green" bases (SASIP

742-1320-94-250). Steel portion of M825 projectile base is

Residue, which is epoxy sealant, will not be affected by

that portion from base/body joint extending rearward for

the acid solution.

one-fourth inch. Damage to protective coating should be

After each test, acid wetted area should be neutralized by

repaired using M825 projectile drawings, provided there is

wiping with a rag wet with bicarbonate solution

no corrosion present.

in paragraph 5b.

d. M825 projectiles may rattle or exhibit other

internal noise when nose is tipped or shaken. This D-28. NSNs for Electrostatic Packing Material

condition is common due to slight looseness of

components and does not affect safety, firing or end item

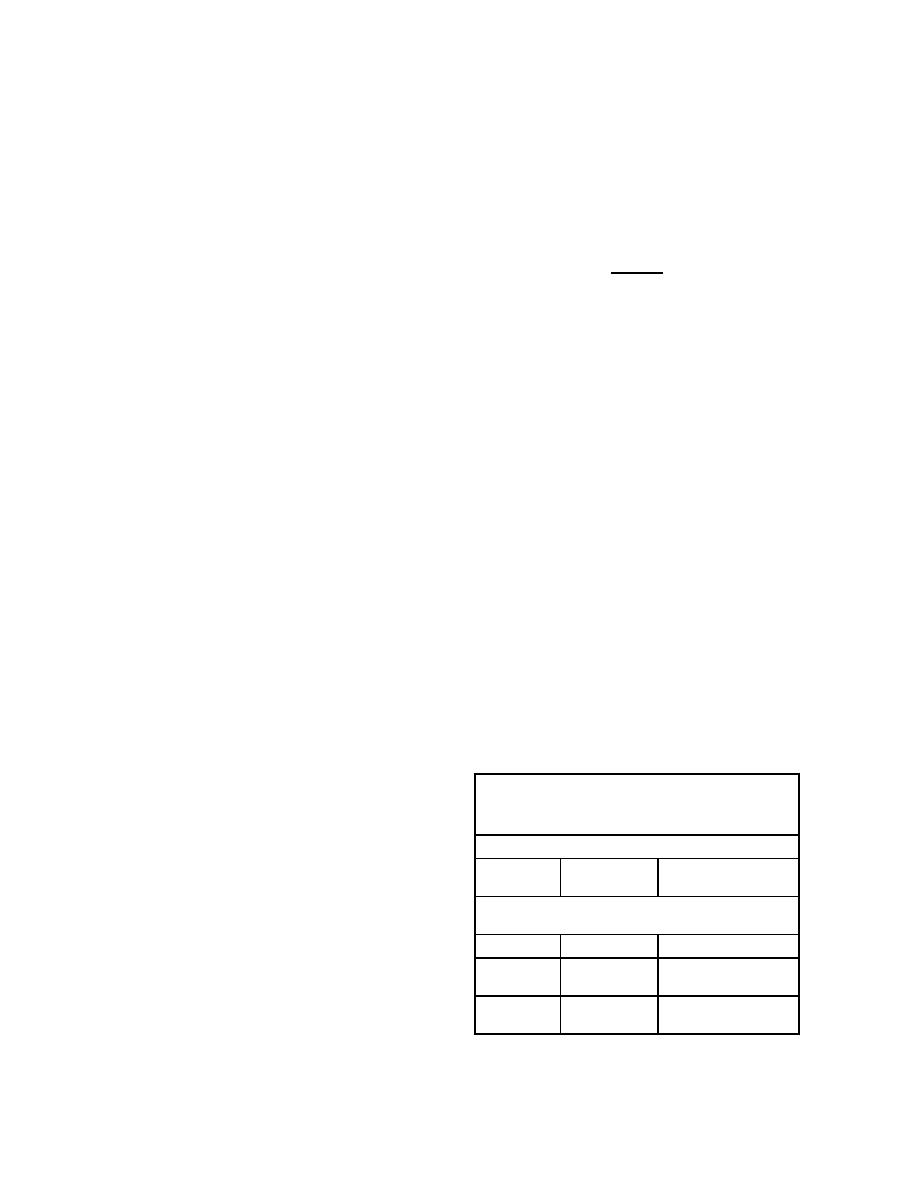

MIL-PRF-81705

performance.

ELECTROSTATIC PROTECTIVE BARRIER

MATERIAL

a. Inspection of 8-inch M404 projectiles will include

NSN

TYPE

SIZE

inspection of expulsion charge bags. Bags may be made of

2-mil low-density polyethylene film that is known to

8135-01-

Type I

36 inches X 150 ft

deteriorate over time due to environmental stress

185-6816

roll

POLYETHYLENE BAG WITH INTERLOCKING SEAL

lifting plug gaskets.

CLOSURE

b. Any crack or tear in an expulsion charge bag is a

NSN

SIZE

major defect if moisture can enter or propellant escape.

Deterioration or damage to lifting plug gaskets to an

10 inches wide X 10

8105-00-

extent, which would permit entry of moisture, is also a

inches length

837-7756

major defect.

12 inches wide X 12

8105-00-

c. Expulsion charge covers can be removed using a

inches length

837-7757

spark proof tool. Following inspection, cover edges are to

be snapped back under the stake marks in the cup using

finger pressure.

Previous Page

Previous Page