SB 742-1

(3) AR 385-63, Policy and Procedures for Firing

Ammunition for Training, Target Practice and Combat, states

SMALL ARMS CARTRIDGES THROUGH CALIBER .50

that units intending to use ammunition lots for overhead fire

must have lots approved for such use. This guidance does not

apply to SAA.

a. FSC: 1305.

e. Class V materiel supplied to non-SMCA customers.

b. Ammunition Type:

Small arms cartridges through

Shipment or transfer of accountability of caliber .22 and blank

caliber .50.

small arms ammunition to non-SMCA customers does not

c. The small arms family of cartridges (through caliber .50) require a functional clearance.

are those which are complete assemblies consisting of all

components necessary to fire a weapon (i.e., cartridge case,

primer, propellant and bullet or shot).

For a complete

a. Profile and alignment gaging and pull and twist tests

description of various cartridges, see TM 43-0001-27 and will be performed during IRI per paragraph 2-8, applicable

applicable drawings.

drawings, and applicable specifications. Pull and twist tests

will also be performed during subsequent cyclic and receipt

inspections.

a. Reasonable care will be taken during inspection and

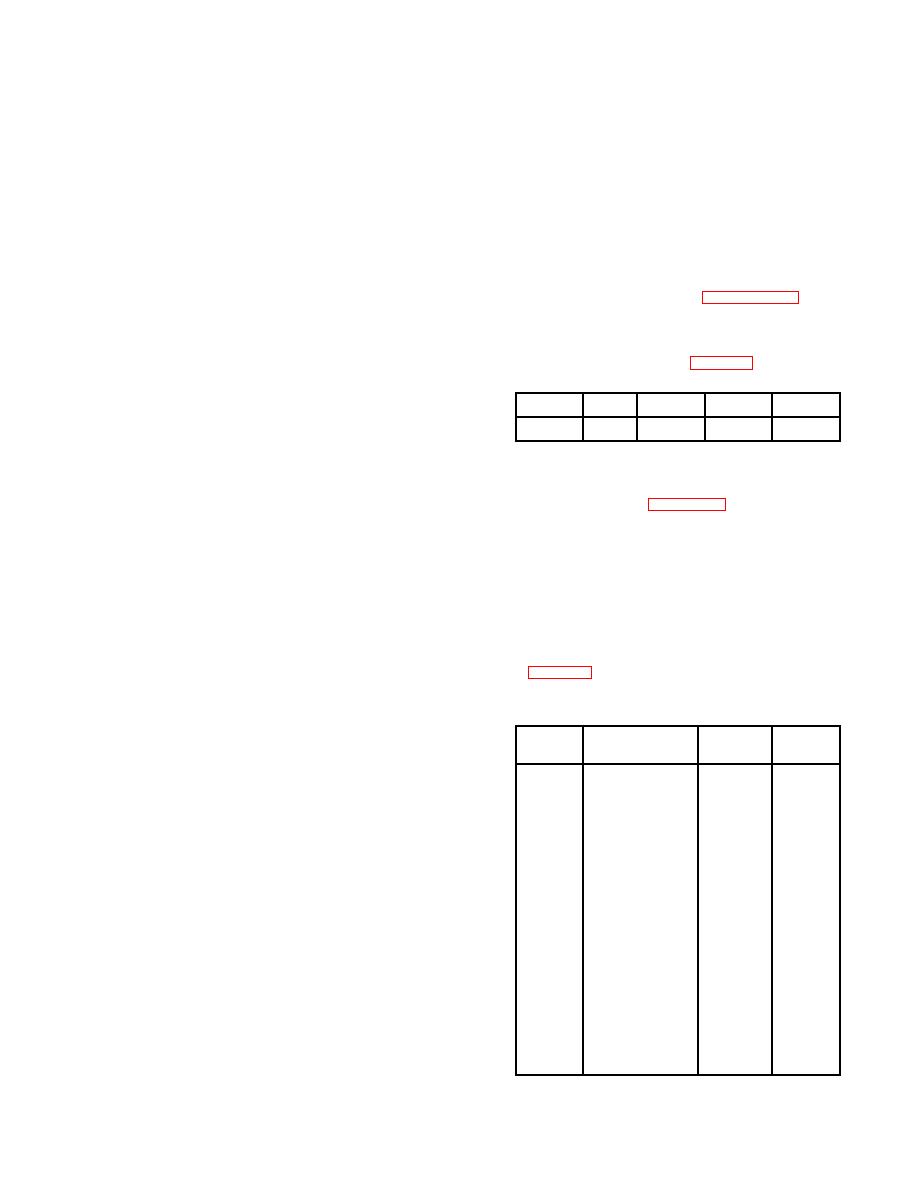

b. Test cartridge according to Table E-1

handling. SAA may function if the primer is inadvertently

struck.

b. To preclude the mixing and issue of other types of SAA

Model

IRI

RI

PI

UBLI

with blank ammunition, the following minimum precautions

All SAA

A,B,C

B,C,D

B,C,D

B,C,D

will be taken:

Legend:

(1) Conduct no operations involving other types of

SAA in bays or rooms in which operations involving blank SAA

A - Profile and alignment gage.

are being conducted.

B - Pull test.

(See

for

specific

pull

(2) Inspect all equipment and work areas prior to use

requirements.)

to insure service rounds are not present.

C - Twist

test.

(See

MIL-STD-644

for

specific

(3) Restrict use of all involved equipment to blank

procedures.)

SAA until the operation is completed.

D - Profile and alignment gaging required only if not

(4) Incorporate controls on linking machines that will

accomplished during IRI, or if round is visibly damaged.

prevent entry of all rounds except blank ammunition.

Lot will not be rejected if damaged round fails to gage.

Gage failures will be reported IAW requirements of

(5) Conduct a 100-percent visual inspection of all

basic SB. (Profile and alignment gaging is required only

rounds prior to linking, clipping or carton packing and another

one time during life cycle of lot.)

100-percent inspection before final packing to assure that only

blank ammunition has been linked/clipped or packed in

c. Table E-2 identifies test and measuring equipment.

cartons.

c. Restrictive marking stenciled on the exterior container

of SAA.

Gage, Profile and Alignment

(1) Prior to 1976, it was common for Frankford

Caliber

NSN

Part

Model

Arsenal to instruct the manufacturers of SAA to stencil the

Number

exterior containers of restricted ammunition prior to

5.56MM

5220001198607

8654100

M193,

containers leaving the manufacturing facility. The restrictions

M195,

were not forwarded to higher headquarters for inclusion in TB

M196,

9-1300-385.

M200,

M855,

(2) There is no available record of the lots with

M856

restrictions stenciled on boxes and it is not anticipated that an

attempt will be made to list these restricted SAA lots in TB

7.62MM

5220001190873

8648501

M59,

9-1300-385.

M61,

(3) Restrictions stenciled on boxes of SAA are

M62,

considered valid and all ammunition lots so marked should be

M64,

issued and used according to these restrictions.

M80,

M82,

d. SAA for overhead fire.

M118,

M160,

(1) SAA intended for overhead fire is manufactured to

M276,

different, more stringent specifications and is identified by

M852

NSN, not by lot number.

(2) Only SAA identified for overhead fire in supply

CAL .30

5220001190871

8648308

M1, M2,

catalog SC 1305/30 IL or DOD Consolidated Ammunition

M14,

Catalog may be used for that purpose.

M25,

M72,

Previous Page

Previous Page