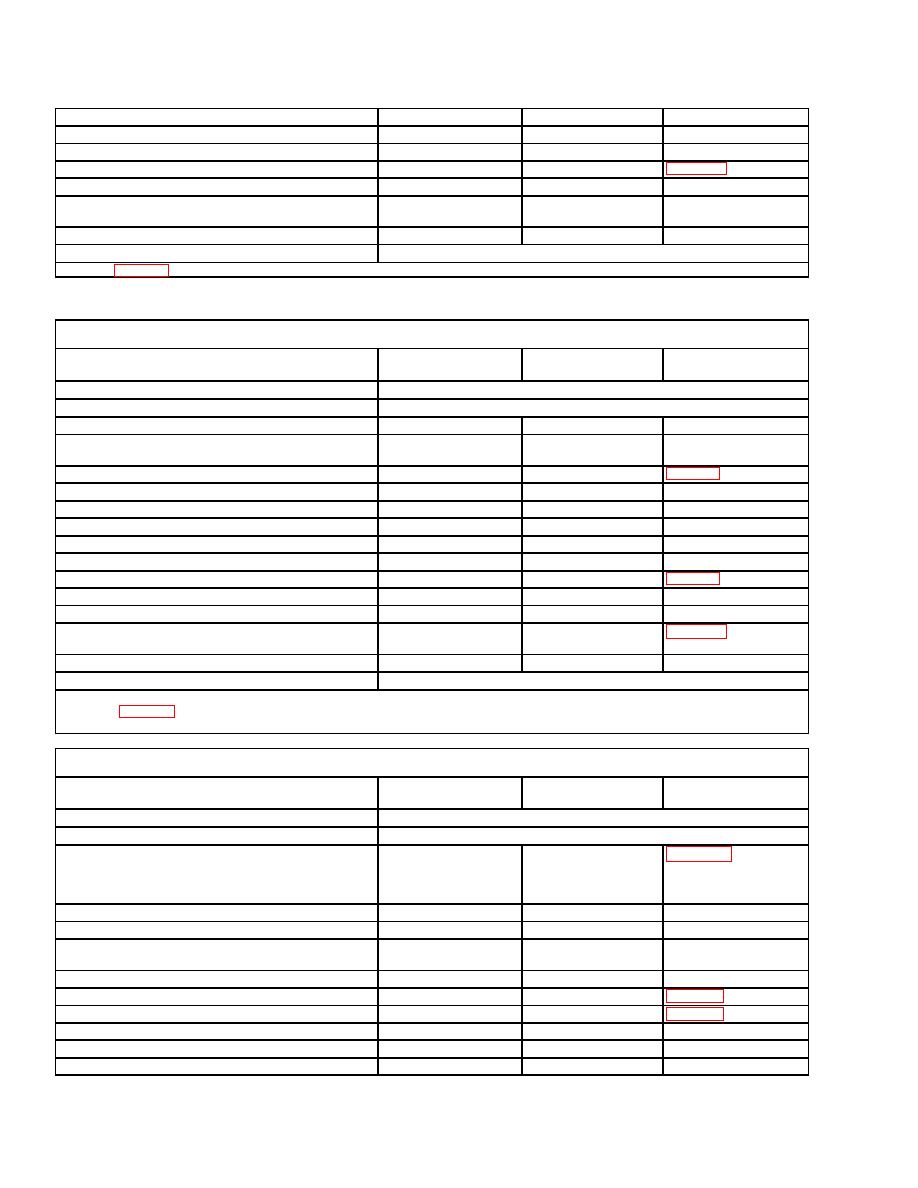

SB 742-1

a. Rear nylon band defective

Visual

b. Sabot cracked

Visual

c. Missing parts

Visual

d. Failure to chamber/gage

Gage

e. Pitting corrosion on projectile assembly

Visual

f. Obturator - loose, cracked or other damage which would

Visual

preclude gas seal

g. Rubber seal on Sabot torn or split

Visual

3. Minor: None Defined

NOTE: See Table L-6 for all combustible cartridge case and case base and seal assembly defect

AND M830A1 (C791, TP-T M831A1 (C784) AND XM908 (CA05)

Classification

Application

Inspection

Inspection

Method

Description

1. Critical: none defined

2. Major:

a. Missing parts

Visual

b. Copper/nylon band damaged to the point of recluding

Visual/gage

chambering

c. Failure to chamber/gage

Gage

d. Spike tip damaged

(M830 & 831A1)

Visual

e. Proximity sensor damaged

(M830A1)

Visual

f. Sabot cracked or pitted

(M830A1 & M908)

Visual

g. Shoulder switch bent or cocked

(M830)

Visual

h. Spike shoulder damaged

(M830)

Visual

i. Projectile rubber seal damaged

Visual

j. Spike Tip loose

(M830)

Visual/Manual

k. Pitting corrosion on projectile

Visual

l. Projectile partially or completely separated from cartridge

Visual/Manual

case

m. Projectile rotates relative to forward adapter

(M830 only).*

Visual/Manual

3. Minor: None Defined

NOTES:

1.

2. *Potential exists for M830 projectile fins to break DIGL-RP stick propellant.

CASE BASE & SEAL ASSEMBLY, 120MM TANK AMMO

Classification

Application

Inspection

Inspection

Method

Description

1. Critical: none defined

2. Major:

a. Abrasion damage or peeling causing coating to be absent in

Visual

one continuous area. Yellow-white nitrocellulose case material

exposed in this area totaling 10% or more of the total cartridge

case surface (30 sq. in. or 192 sq. cm).

b. Case broken exposing internal propellant containment bag

Visual

c. Skive joint (glue joint at case shoulder)separation

Visual

d. Case base and seal assembly (CBSA) separated from

Visual

cartridge case body

e. CBSA rubber seal torn or separated

Visual

f. Primer above flush

Visual/Manual

g. Primer stake missing or does not engage primer

Visual

h. Corrosion of CBSA with visible pitting

Visual

i. Non-removable corrosion on primer

Visual/Manual

j. Shoulder or sidewall of case cracked, punctured, dented or

Visual

Previous Page

Previous Page