SB 742-1

split

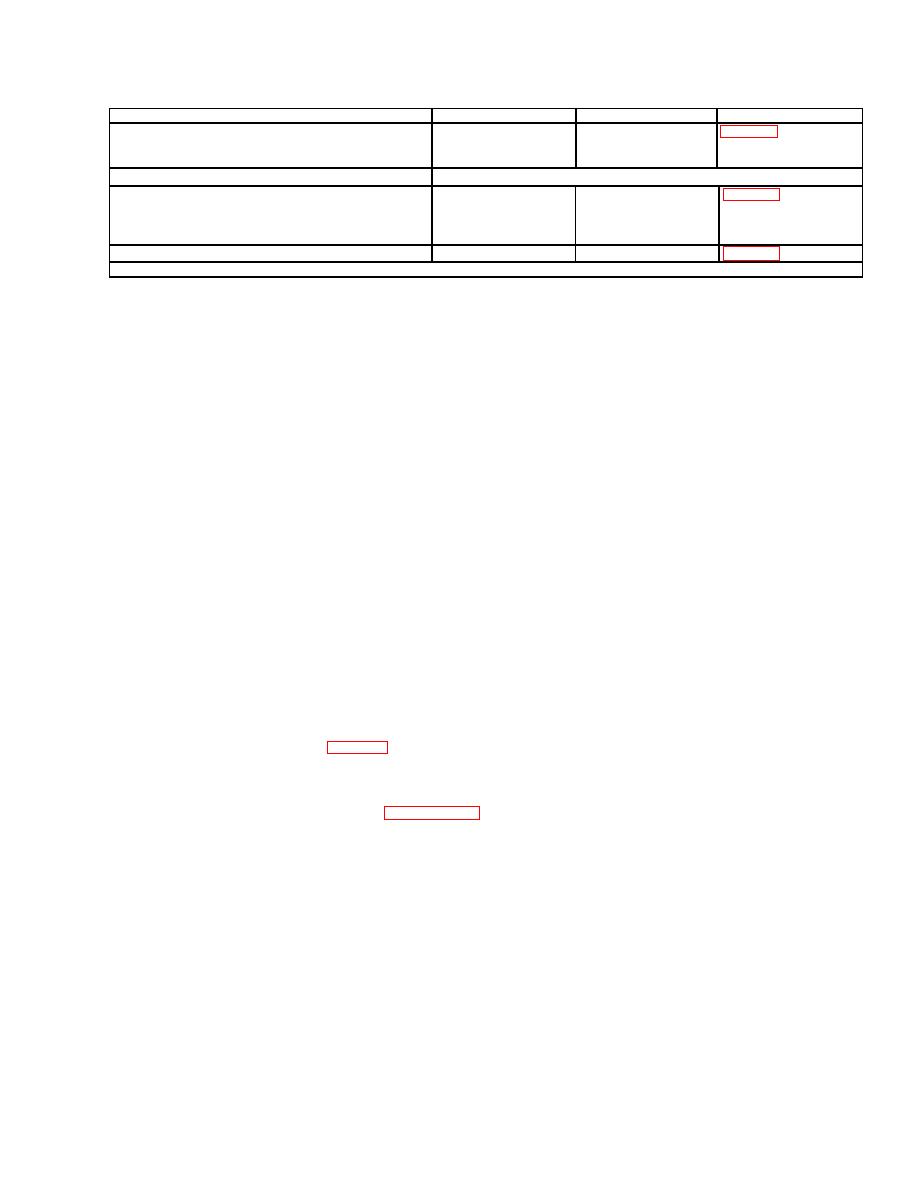

k. Evidence of moisture damage resulting in a softening or

Visual/Manual

penetration of the combustible ctg. case (CCC) or forward

adapter

3. Minor:

a. Abrasion damage/peeling causing coating to be missing in

Visual

one continuous area. Yellow-white nitrocellulose case material

seen on this area totaling more than 0.25 sq/in or 1.6 sq/cm, but

less than 10 percent of total surface.

b. Water mark on cartridge

Visual

NOTE: The M830 (C787) has a live forward adapter.

(1) Cartridge deformation

(profile

misalignment)

preventing gaging or chambering.

a. Movement between sub-projectile and sabot is

(2) Evidence of propellant dusting on outside of

permissible and shall not be considered a defect. M829,

M829A1, and M829A2 projectile rotation at the case cartridge case or projectile.

adapter/obturator joint is permissible.

(3) The affected cartridge is either an M829A2 (C792)

b. Sabot segment gaps are permissible provided that the or M830 (C787) or M829A3 (CA26) with stick propellant that

could become damaged by the movement of penetrator fins or

cartridge can be chambered.

projectile boom/fins.

c. The M829 projectile contains a forward nylon-centering

i. Testing has demonstrated that the electric primer

band composed of four individual segments attached to sabot

petal. The gaps between centering band segments are aligned assembled to the round is insensitive to initiation by

with sabot segment gaps. The M829A1 projectile does not mechanical impact. Therefore, primers and igniters above

contain a forward centering band. The M829A3 contains a flush are considered major defects, rather than critical. Any

composit ring composed of three segments attached to the straight edge rule is suitable for checking primers for an above

petals. A blue adhesive is used to bond the ring. Adhesive is flush condition. The primer shall be staked to the case base.

For lots manufactured CY 02 and later, the stake shall be a

visible.

single indentation applied to the case base and material must

d. The M829, M829A1, M829A2, and M829A3 projectile be displaced into the primer. For lots manufactured before

assemblies contain a Depleted Uranium (DU) fin stabilized CY02, absence of primer stake or primer stakes that do not

penetrator.

The M829 series sub-projectiles consist of a clearly engage the primer are not considered defective if primer

penetrator, windshield, and fin. The number of sabot petals is not loose.

and their composition material vary. The M865 TPCSDS-T

j. Any cut, nick, or gouge in the projectile rubber seal

projectile assembly consists of a steel core encased in three

aluminum sabot segments attached to rubber obturator and (M830 or M831A1) more than one half the width or more than

2 inches in circumference shall be cause for rejection.

steel stabilizer.

k. Moisture noted within PA-116 containers indicates

e. Container dents that are less than inch do not

ammunition was either wet when containerized or the interior

require repair. Dents greater than inch that impair the

components of the PA-116 were wet when the ammunition was

structural integrity of the PA-116 container or prevent the

packed out. Containers with wet interior projectile supports

removal of the cartridge are major defects. A cartridge that

and spacers are considered unserviceable until the moisture

cannot be removed from the PA-116 shipping and storage

intrusion condition is corrected. Cartridges found in such

container shall be placed in CC-F and reported by ACR with

containers must be closely examined for moisture damage

info copy by email to the office in para 1-5d(1). Cartridges

according to the applicable tables.

removed from damaged containers that evidence dented

cartridge cases shall be placed in CC-H and reported by ACR

l. QASAS will inspect cartridge cases for evidence of

as above.

moisture, dents, or penetration.

Defects can result from

packaging or the cartridge not being dry at time of packaging,

f. Perform chamber gaging according to paragraph L-3.

upload, and download operations during inclement weather, or

Standard ring gage set may be used in absence of man

exposure to standing water or heavy condensation in the

portable chamber gage.

NOTE:

Ring gages will detect

bustle and hull ammunition storage racks. Inspect for water

oversized conditions for their specific profile dimension.

However, gaging with projectile and case ring gages will not

damage, soft cartridge cases, and forward adapters which

detect an out-of-alignment condition at the mating point of the

easily deform under hand pressure, water marks indicating

projectile assembly and cartridge case forward adapter.

case exposure to standing water and metal parts rust or

Therefore, where available, the MPCG is the preferred gaging

corrosion.

method to properly verify the entire profile and alignment of a

m. A windshield with a single longitudinal crack less than

120MM cartridge.

two inches in length is considered an incidental defect.

g. Any deformity (such as tip bluntness or off-center

n. Cartridge cases that have yellowish-white combustible

displacement) of the windshield tip may affect the aero-ballistic

material showing, less than 10 percent of the total surface area

performance of the sub-projectile.

of the cartridge case, will be touched up IAW procedures

h. Samples with projectiles exhibiting movement in contained in TM 9-1300-251-34&P.

relation to the cartridge case are not considered defects unless

o. The projectiles are marked with white alignment marks

one or more of the following conditions are also noted:

on the sabot and windshield. There are two marking schemes.

The first scheme has one mark on the sabot and one on the

Previous Page

Previous Page