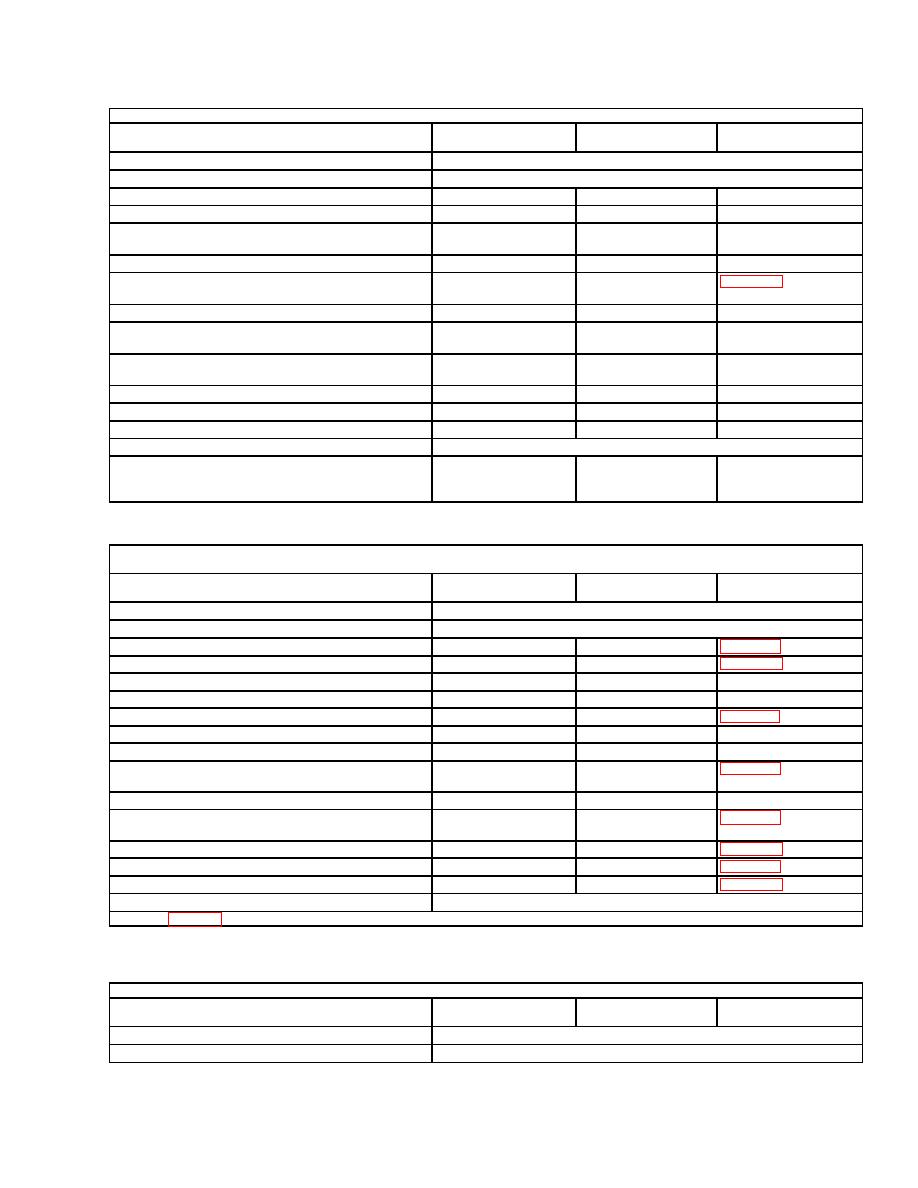

SB 742-1

Classification

Application

Inspection Method

Inspection

Description

1. Critical: none defined

2. Major:

a. Cover Assembly nonfunctional

Visual

b. Gasket missing or defective

Visual

c. Internal components/packaging missing or

Visual

defective

d. External components missing or defective

Visual

e. Dents greater than inch deep that prevent

Visual

cartridge extraction

f. Perforations/holes

Visual

g. Internal components/packaging moisture

Visual

soaked

h. Markings illegible, precluding proper

Visual

identification of nomenclature and lot number

i. IM panels perforated/cracked

(M829A3 only)

Visual

j. IM panel gaskets missing or defective

(M829A3 only)

Visual

k. Separation of top flange around IM panel

(M829A3 only)

Visual

3. Minor:

a. Protective finish on container body (not rims

Visual

and.rings) with pitted corrosion over 10 percent of

surface

M829 (C786), M829A1 (C380), AND M829A2 (C792) AND M829A3 (CA26)

Classification

Application

Inspection Method

Inspection

Description

1. Critical: none defined

2. Major:

a. Failure to chamber/gage

Gage

b. Sabot segments misaligned

Visual

c. Rear Obturator cracked/damaged

Visual

d. Sabot cracked

Visual

e. Front bourrelet rings cracked

Visual

(M829A3 only)

f. Missing components

Visual

g. Cracked cartridge case forward adapter

Visual

h. DU corrosion (yellowish or black powder or staining) in

Visual

sabot gaps and/or windshield interfaces

i. Corrosion on projectile body causing pitting

Visual

j. Projectile partially or completely separated from. the

Visual

combustible cartridge case.

k. Marks on sabot and windshield not aligned properly

Visual

(M829A1 only)

l. Windshield damage (dents, blunt tip etc.)

Visual

m. Primer or igniter above flush

Gage

3. Minor: None Defined

NOTE: See Table L-6 for all cartridge case and case base defect criteria

Classification

Application

Inspection

Inspection

Method

Description

1. Critical: none defined

2. Major:

Previous Page

Previous Page