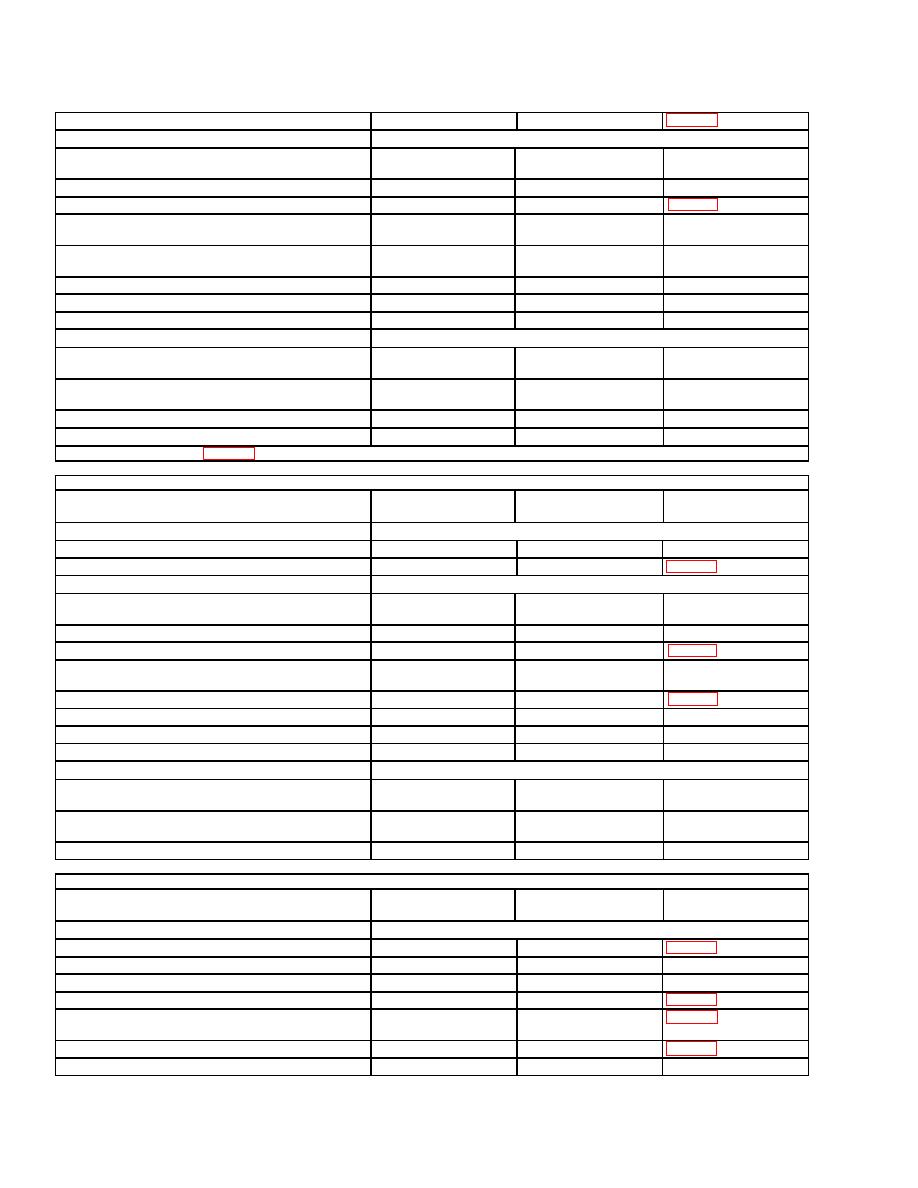

SB 742-1

c. Gouge in warhead

Visual/depth gage

2. Major:

a. Corrosion/rust on metal surfaces or threads extensive

Visual

enough to prevent assembly and/or effect metal integrity

b. Damaged threads that would prevent assembly

Visual

c. Gouge in warhead

Visual/Depth Gage

d. Blistering or peeling paint that would require complete

Visual

repainting

e. Marking illegible/obliterated to extent that item cannot be

Visual

positively identified

f. Plastic nose cone damaged or loose

Flechette

Visual

g. Damaged or bent umbilical connector

XM255E1,M261, M267

Visual

h. Damaged umbilical cord

XM255E1, M261, M267

Visual

3. Minor:

a. Light corrosion/rust that does not affect assembly or metal

Visual

integrity

b. Markings faded, dim and/or partially illegible, but item

Visual

can be identified

c. Paint blistering or peeling in spots

Visual

d.

Visual

Scratches through entire protective coating

Note: For fuzed warhead, see table U-5 for defect criteria on fuze

TABLE U-5. Fuze

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Crack or dent in fuze body

Visual

b. Gouge in fuze body

Visual/Depth Gage

2. Major:

a. Corrosion/rust on metal surfaces or threads extensive

Visual

enough to prevent assembly and/or affect metal integrity

b. Damaged threads that would prevent assembly

Visual

c. Gouge in fuze body

Visual/Depth Gage

d. Marking illegible/obliterated to extent that item cannot be

Visual

positively identified

e. Loose ogive on fuze

M423 and M427

Visual

f. Umbilical assembly missing

remote set fuzes only

Visual

g. Protective cap missing or damaged

M433

Visual

h. Dents, gouges or scratches in impact switch

M433

Visual

3. Minor:

a. Light corrosion/rust that does not affect assembly or metal

Visual

integrity

b. Markings faded, dim and/or partially illegible, but item

Visual

can be identified

c. Scratches through entire protective coating

Visual

TABLE U-6. Motor

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Cracks, dents, or gouges in motor tube

Visual

b. Hole in motor tube forward bulkhead

Visual

c. Bulge on motor tube

Visual

d. Shorting clip missing or improperly positioned

MK 40 motor

Visual

e. Electromagnetic Radiation Shield (EMR) missing or

MK 66 Mod 3

Visual

damaged

f. Broken lead wire

Visual

g. Loose nozzles on nozzle and fin assembly

Mk 40 Motors

Manual

Previous Page

Previous Page