SB 742-1

(b) Rocket Motor MK22 Series: A 5" rocket motor

CHARGE, DEMOLITION, HE, LINEAR M58 SERIES AND

is used to tow the linear charge across the minefield. Item

CHARGE DEMOLITION, PRACTICE, M68 SERIES

description and inspection criteria are contained in TM 9-

1375-215-14 & P, Operator's, Unit, Direct Support, and

General Support Maintenance Manual Including Repair Parts

a. FSC: 1375.

and Special Tools List - Demolition Kit Mine Clearing Line

b. Ammunition type: Charge, Demolition, High Explosive Charge (MICLIC).

Linear M58 Series and Charge, Demolition, Practice M68

(2) Charge, Demolition, Practice, M68 Series. The

Series.

item is a non-explosive linear charge used only for training

c. Mine Clearing Line Charge (MICLIC) is a trailer sessions. Rubber is used to simulate the explosive pellets in

mounted, rocket-towed demolition charge used to provide a the unit charges. The charge can be launched a maximum of

clear path for combat vehicles during minefield breaching three times. The M68 series contains an inert fuze, but uses a

operations. The MICLIC is capable of clearing a path 14 live MK22 series rocket motor.

meters wide by 100 meters long through a minefield. The V-2. Unique safety precautions.

launcher and trailer are fully reusable, and can be reloaded in

Do not operate radio frequency transmitters within five feet of

thirty minutes.

the M58 Series charge, or rocket motor. Safe distances from

d. The two linear charges available for use with the system high-powered transmitters are included in Chapter 6, DA PAM

are:

385-64. Positive steps (conductive floor, mats, etc.) will be

(1) Charge, Demolition, High Explosive Linear M58 taken to eliminate static discharges.

Series. The charge assembly consists of PETN detonating V-3. Testing and equipment requirements.

cords and 700 Composition 4, unit charges, 2.5 pounds each,

secured to 350 feet of nylon arresting cable. The primary Table V-3 identifies depth gage and

wrench

requirements.

explosive components are:

(a) Fuze, Electric, M1134 Series. The fuze is

included in the container, but is separately packaged and is

a. Inspection Category X: periodic inspection interval--4

not connected to the charge assembly until item is prepared for

years.

Periodic inspection sample size and accept/reject

deployment. Safe/arm mechanisms prevent initiation of the

criteria will be according to chapter 2.

linear charge prior to launch. A window in the cylinder side of

the fuze allows display of the safe/arm status of the fuze (green

b. Charges held by using units in Basic Load will be

for safe, red for armed).

inspected on an annual basis according to chapter 9 and this

appendix.

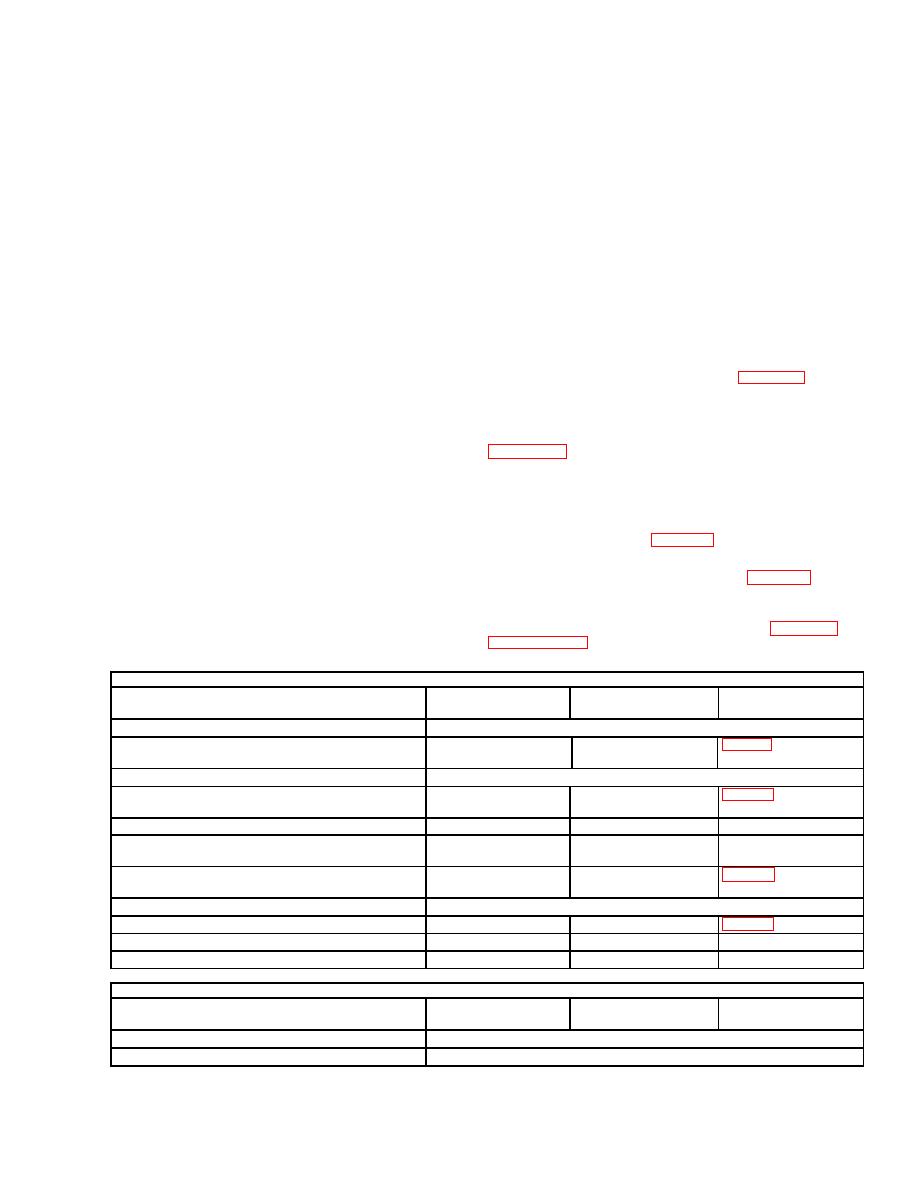

inspected and defects classified according to chapter 2 and

through

V-4

of

this

appendix.

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Warning stencil (or decal) on pallet cover or pallet back

Visual

missing or illegible

2. Major:

a. . Damage to container exposing contents, or preventing

Visual

intended use (penetration, dents, etc.)

b. Cover not secured properly in place

Visual

c. Rust or corrosion compromising container integrity or

Visual

markings

d. Rocket motor electrical receptacle (bottom receptacle)

Visual

detent not in proper position

3. Minor:

a. Strapping loose, broken or improperly applied

Visual/Manual

b. Protective coating (paint) missing

Manual

c. Marking missing, misleading or unidentifiable

Visual

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

None defined

2. Major:

Previous Page

Previous Page