SB 742-1

h.

Visual/Manual

Nozzle and Fin Assembly loose, cracked, dented, gouged

or distorted

i. Missing, cracked or damaged fin hinge pin

Visual

j. Missing or damaged fin(s)

Visual

k. Shielding and fin restraint band missing/damaged

MK66, MODS 1,2 and 4

Visual

l. Missing/damaged end shield

MK 66 Motor all Mods

Visual

Para U-6k and 7

2. Major:

a. Corrosion/rust on metal surfaces or threads extensive

Visual

enough to prevent assembly and/or affect metal integrity

b. Damaged threads that would prevent assembly

Visual

c. Blistering or peeling paint that would require complete

Visual

repainting

d. Marking illegible/obliterated to extent that item cannot be

Visual

positively identified

e. Lock wire distorted or improperly assembled protrudes

Visual

above surface of rocket motor tube

f. Missing contact disc or fin retainer

MK 40 motor

Visual

g. Dent or bulge in EMR shield

MK 66 Mod 3

Visual

h. Igniter circuit resistance not within prescribed limits

Test

i. Missing, damaged or loose nozzle seal/blow out seal

MK 40 motor

Visual

j. Missing or damaged weather seal

MK 66 motor

Visual

3. Minor:

a. Light corrosion/rust that does not affect assembly or metal

Visual

integrity

b. Markings faded, dim and/or partially illegible, but item

Visual

can be identified

c. Paint blistering or peeling in spots

Visual

d. Scratches through entire protective coating

Visual

e. Shielding/fin restraint band improperly positioned or tape

Visual

holding band to nozzle missing

e. For MK 66 motors, check to see if the end shield is

damaged and requires replacement.

a. In pre-1970 designs, a loose ogive (with rotation but

without longitudinal looseness) does not represent a

f. Gap is considered to exist if component is not seated for

performance, safety or storability problem. For post-1970 a full 360 degrees.

designs, a loose ogive could represent a storability problem

g. Criteria for gouge in warhead:

(seal broken) and is considered a major defect. The following

defines P/ns for the different fuze designs:

(1) M156, M257, M259, M264, M78: a gouge with

visible depth will be considered a critical defect.

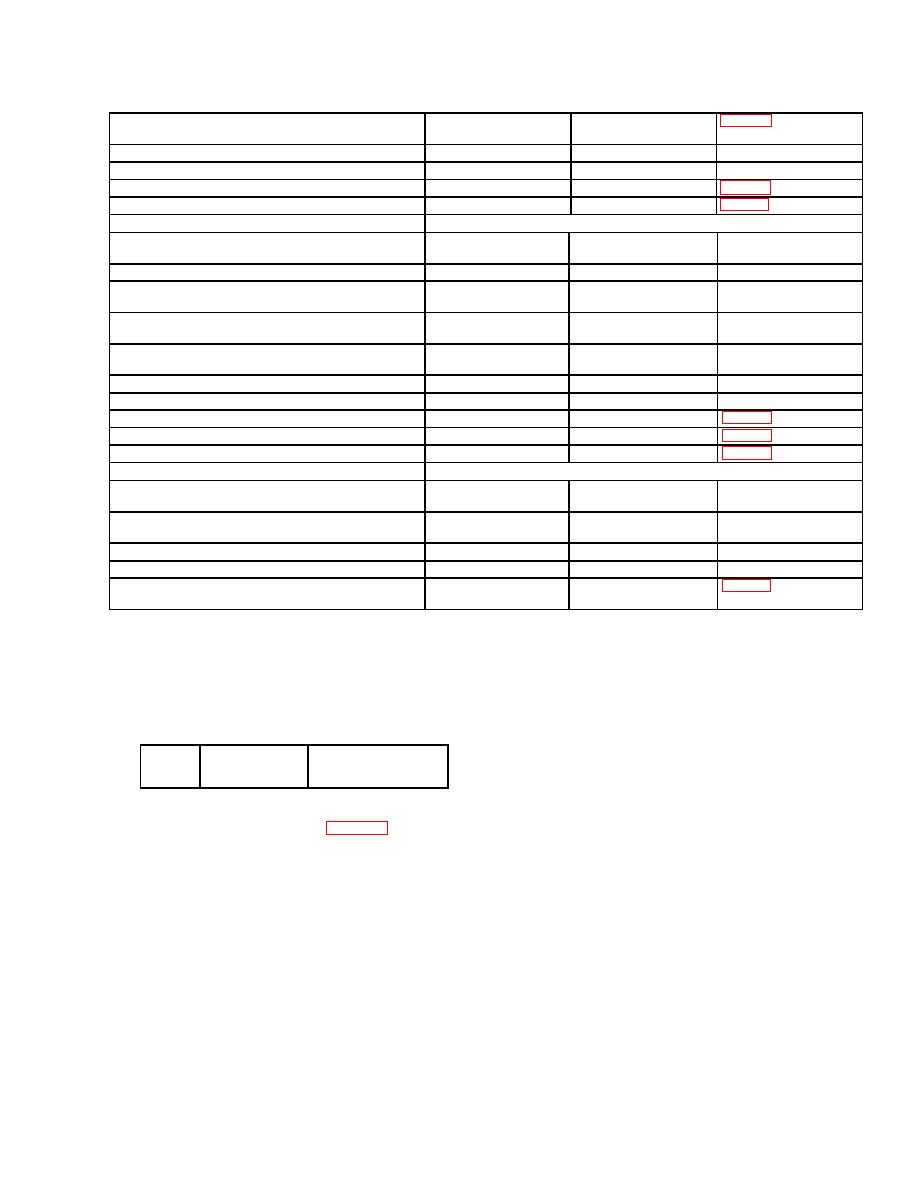

Fuze

Pre-1970 P/N

Post-1970 P/N

(2) XM255E1, M261, M267, WDU-4A/A: a gouge with

M423

8883683

9254708-1

visible depth will be considered a major defect.

M427

8883745

9254708-2

h. M151, M229, M230, M247, M274, WTU-1/B: a gouge

b. Torque test

having a depth of 1/16" or more and length of " or more will

(1) Torque fixture listed in table U-2 (formerly APE be considered a critical defect; other gouges will be considered

2075M1) will be used. Warheads without fuze wrench slots a major defect.

may be tested using a torque wrench adapter that must be

i. Criteria for gouge in fuze body: a gouge having a depth

locally fabricated using drawing AXMRR-7507A. This drawing

of 1/16" or more and length of " or more will be considered a

may be obtained from DAC, McAlester, OK .

critical defect; other gouges will be considered a major defect.

(2) A line will be scribed or drawn across the

j. Shielding/fin restraint band is considered damaged if it

junctions (fuze to warhead and warhead to motor) to provide a

contains a hole or cut through entire thickness within one inch

means of detecting movement between components.

55

of its aft edge. EMR shield is considered damaged if it contains

foot-lbs torque will be applied in a tightening direction. Any

a hole or crack within one inch of the aft edge of the EMR

movement at less than 55 foot-lbs is a test failure.

shield.

c. Do not attempt to twist nozzle assembly. Should the

k. End shield is considered damaged if it contains a hole

nozzle assembly wobble or move lengthwise, it is defective.

(other that fin pin holes) or cut through entire end shield. The

d. Perform igniter circuit resistance test IAW Ammunition end shield is bonded to the aft face of the nozzle.

Peculiar Equipment Operational Manual and Parts List For

APE 1189 Rocket Motor Continuity Tester. Igniter circuit

resistance limit is MK 40 series Motor: .63 to 4.0 ohms

Previous Page

Previous Page