SB 742-1

maintained inverted in storage. Orientation of box should be

an inspection point at time of sample selection.

FUZES, ARTILLERY

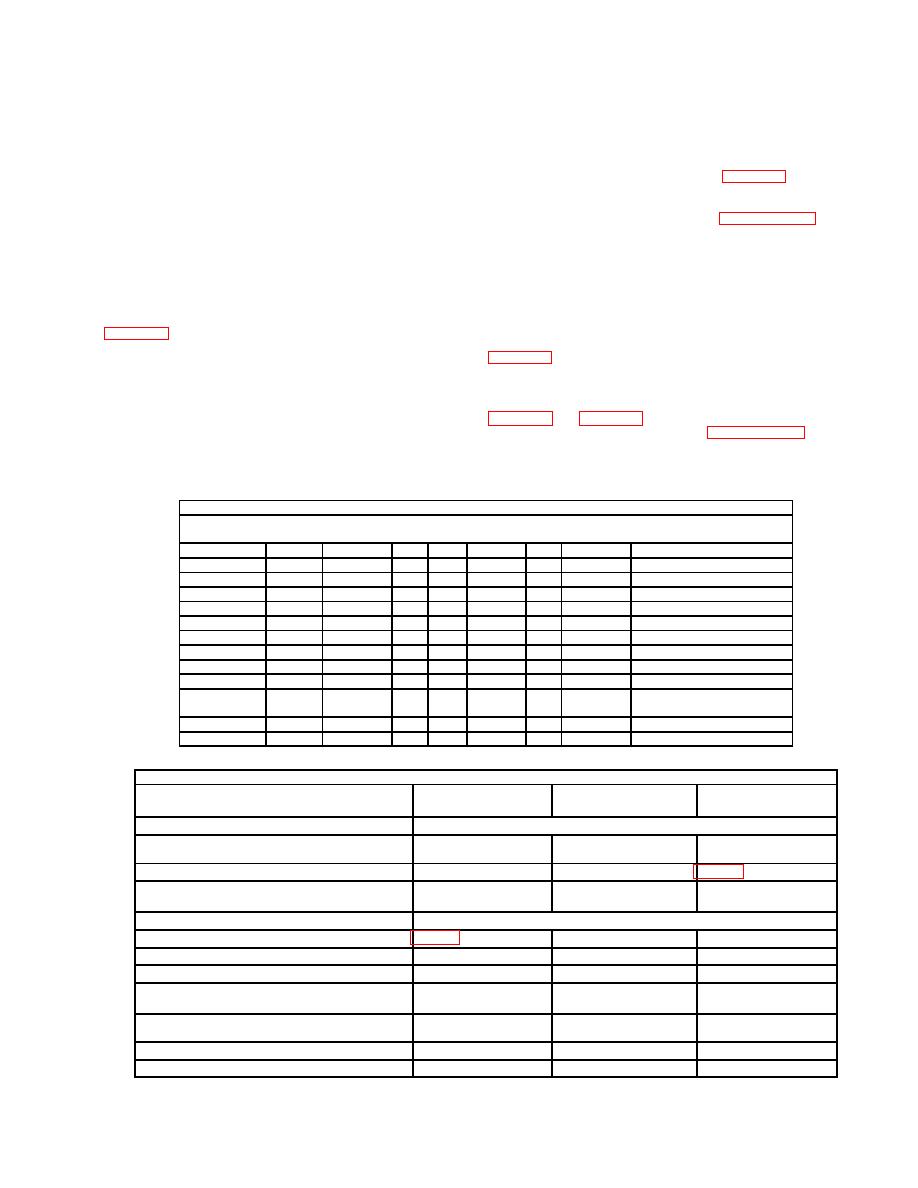

a. Torque test fuzes according to table X-1 utilizing the

a. FSC: 1390.

APE 1223 torque fixture. Torque test of the fuzes during

b. Ammunition Type: Artillery fuzes, including mechanical receipt inspection will be conducted on a sampling basis as

time (MT), mechanical time super quick (MTSQ), point deto- determined by the QASAS in charge. Paragraph 2-2b(1) and

nating (PD), proximity (VT) and electronic time (ET). Mortar (2) apply. This determination should be based on past and

fuzes included in other appendices are not covered.

present inspection data.

c. The M544 fuze is a M501A1 fuze modified by adding a

b. The M571, M592 and M711 fuzes are hand settable

XM137 booster and is assembled only to the M413 105mm HE with a plunger which provides locking of lower cap in flight and

cartridge.

do not require a fuze setting torque test.

d. For a complete description and related data, refer to X-4. Inspection category and sampling plan.

The inspection interval and sampling will be according to

Class 1315, 1320 and 1390) and applicable Drawings.

a. No unique safety precautions are applicable to this

a. Item will be inspected and classified according to

item.

b. Proximity fuze M732 is required to be stored base up packing materiel will be according to paragraphs X-6g and h.

according to drawing 19-48-4116-PA1002/156G.

This

prevents deterioration of power supply. Container requires

stencil marking with an arrow, pointing toward bottom of

wirebound box and word "up".

Containers should be

# Below Min

# Above Max

Torque limits Sample _________________________________________________

Model

Inspection Inch-Pounds Size Accept Accept Reject

Reject

Application

M501, MTSQ

RI, PI

50-300

20

2

3

2

3

Lower cap assembly

M501A1, MTSQ RI, PI

50-300

20

2

3

2

3

Lower cap assembly

M520, MTSQ

RI, PI

50-300

20

2

3

2

3

Lower cap assembly

M520A1, MTSQ RI, PI

50-300

20

2

3

2

3

Lower cap assembly

M544, MTSQ

RI, PI

50-300

20

2

3

2

3

Lower cap assembly

M548, MTSQ

RI, PI

60-300

20

1

2

2

3

Lower cap assembly

M563, MT

RI, PI

60-300

20

1

2

2

3

Lower cap assembly

M564, MTSQ

RI, PI

60-300

20

1

2

2

3

Lower cap assembly

M565, MT

RI, PI

60-300

20

2

3

2

3

Lower cap assembly

M514A3, PROX. RI, PI

100-300

20

2

3

2

3

Lower cap assembly

RI, PI

M728, PROX

RI, PI

100-300

20

2

3

2

3

Lower cap assembly

M732, PROX

RI, PI

100-300

20

2

3

2

3

Lower cap assembly

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Fuze with missing or broken safety pin or clip

M501A1

Visual

M520

b. Fuze not set to safe "S" position

M564

Visual

c. Ogive and head assembly loose (removable by hand M48-series, M51-series,

Visual/Manual

M557, M572

pressure)

2. Major:

a. Cracked Ogive

Visual

b. Threads damaged to the extent precluding assembly

All

Visual

c. Pull wire not inserted proper depth

M520

Visual

d. Fuze not set on muzzle action (MA). MA line on

M563, M571, XM711

Visual

lower cap not in line with zero line on body

e. Ogive loose interferes with setting sleeve

M48-series, M51-series

Visual

M557, M572

f. Hairline and number not visible through window

M577, M582

Visual

g. Fuze setting not in shipping position (93.5-95.5

M577, M582

Visual

Previous Page

Previous Page