SB 742-1

individual rounds having visual evidence of damage or other

CARTRIDGE, 4.2 INCH MORTAR

conditions that may preclude loading and firing. Unless the

rounds requiring gaging are truly representative of the lot

being inspected, they should be disregarded in evaluating the

a. FSC: 1315.

lot.

b. Ammunition type: Cartridge, 4.2 inch Mortar. Includes

b. Table K-1 identifies test and measurement equipment.

the following models: M328 series (WP), M329 series (HE),

M335 series (illuminating), and the M630 (tactical CS). The K-4. Inspection category and sampling plan.

M2 series WP or PWP and the M3 series HE are obsolete and

not specifically addressed in this appendix. If these models are

a. Inspection category.

encountered they should be inspected and classified using the

(1) Category V: 6 years (includes jungle pack HE and

applicable portions of this supply bulletin as a guide.

WP.

c. The 4.2-inch cartridges are spin-stabilized rounds fired

(2) Category W: 5 years (includes inert items and

from a rifled bore muzzle loading weapon. For a complete

description of these rounds, see TM 43-0001-28 and the jungle pack illuminating cartridges.

drawings for the particular round.

(3) Category X: 4 years (includes CS in jungle pack

and HE and WP not in jungle pack).

(4) Category Y:

3 years (includes illuminating

WP cartridges manufactured prior to 1966 may contain

cartridges not in jungle pack and bulk ignition cartridges or

bursters loaded with tetrytol. Lots, which contain tetrytol

bursters, will be placed in condition code F for replacement of propellant).

bursters.

Screening for evidence of explosive growth or

(5) Category Z: 2 years (includes CS not in jungle

exudation prior to issue for use is not considered practical or pack and bulk primers)

timely.

b. The sampling plan for inspection is according to

a. All IRI samples will be gaged using a profile and K-5. Specific inspection points.

alignment gage and concentricity gage. Gaging is not normally

a. Item will be inspected and classified according to

required during PI, RI, or UBLI.

Gaging, during these

chapter 2 and table K-2.

inspections (other than IRI), should be limited to

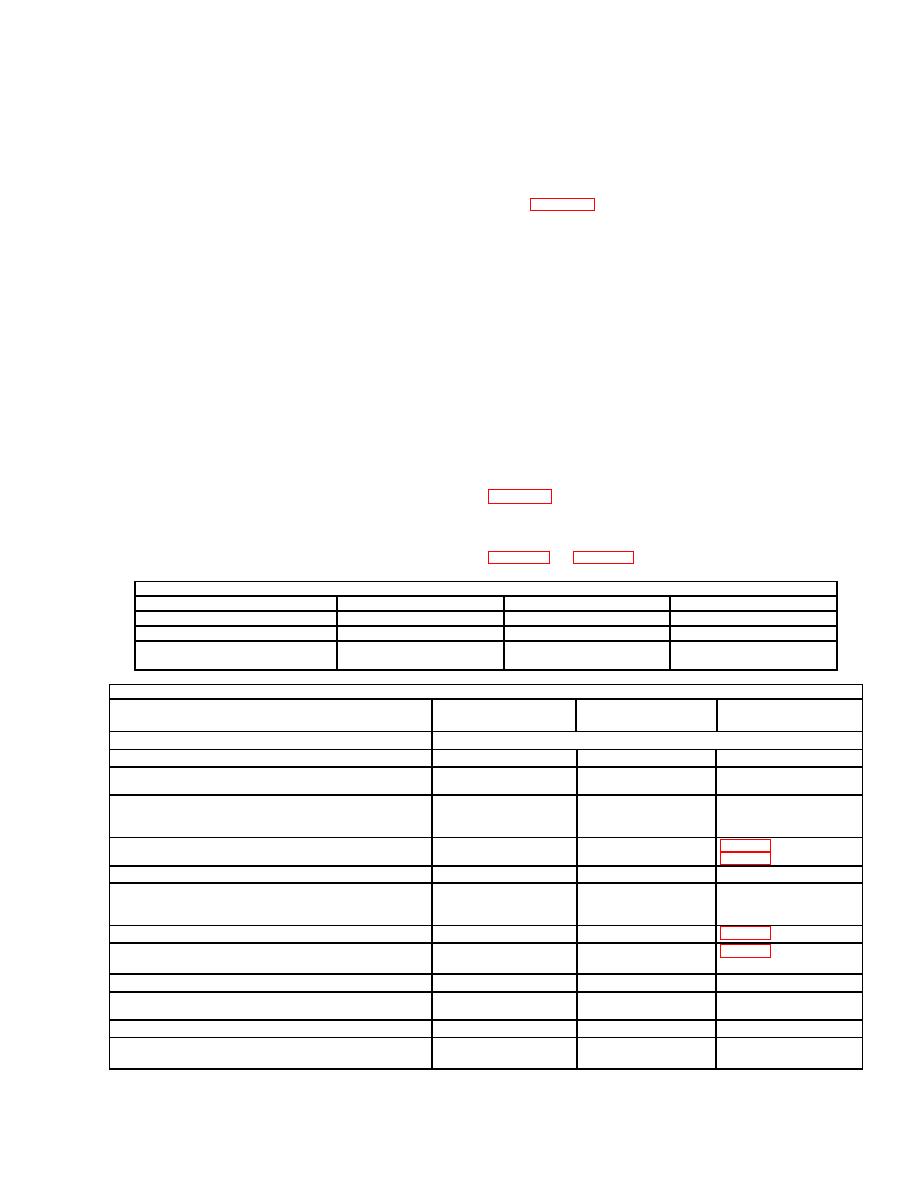

Description

NSN

Application

Inspection

Gage, profile and alignment

9278618

M329A2

Gage, profile and alignment

7258457

All except M329A2

Gage, depth and concentricity

7304529

M329 series unfuzed

deep cavity

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Excessive number of increments

All

Visual

b. Insufficient number of increments

M328 series M329 series

Visual

Visual

c.

M328A1 M329A1

Visual

Bag loading assembly missing or damaged to the extent

M329A2

Visual

that propellant can escape

Visual

d.

M329

Visual

Pressure plate incorrectly assembled (reversed)

M329A1

Visual

e. WP leakage or evidence of leakage

M328 series

Visual

f. Zone weight markings incorrect

M328 series

Visual

M329

Visual

M329A1

Visual

g. Fuze not set on safe (except for Fuze, MT, M565)

Visual

h. Fuze safety wire or pin missing, broken, insecure or

Visual

improperly engaged

i. Supplementary charge pad missing

M329 series (unfuzed)

Visual

j. Fuze well liner missing

M329 series

Visual

(unfuzed)

k. Explosive extends above the top of the fuze well

M329 series (unfuzed)

Visual

l. Fuze well liner not fully expanded and not making contact

M329A2 (unfuzed)

Visual

with fuze well threads for full 360 degrees

Previous Page

Previous Page