SB 742-1

Classification

Application

Inspection

Inspection

Method

Description

1. Critical: none defined

2. Major:

a. Excessive lateral movement of

Visual/Manual/Gage

projectile

b. Primer or igniter above flush

Visual/Gage

c. Primer staking missing

Visual

d. Windshield or windshield tip bent

Visual

or damaged

e. Windshield loose (lateral or

Manual

longitudinal looseness only)

f. Bourrelet cracked or loose

Visual

g. Sabot cracked

Visual

h. Missing parts (e.g., bourrelet,

Visual

obturator, windshield tip, bourrelet

screws).

i. Hose clamp not removed from

Visual

around sabot (reference TM 9-2350-

series or dwg 9296707)

j. Obturating band damaged (i.e.,

Visual

cracked, broken, or gouged)

k. Failure of cartridge to gage

Gage

3. Minor:

a. Windshield cushion missing

Visual

b. Evidence of poor workmanship

Visual

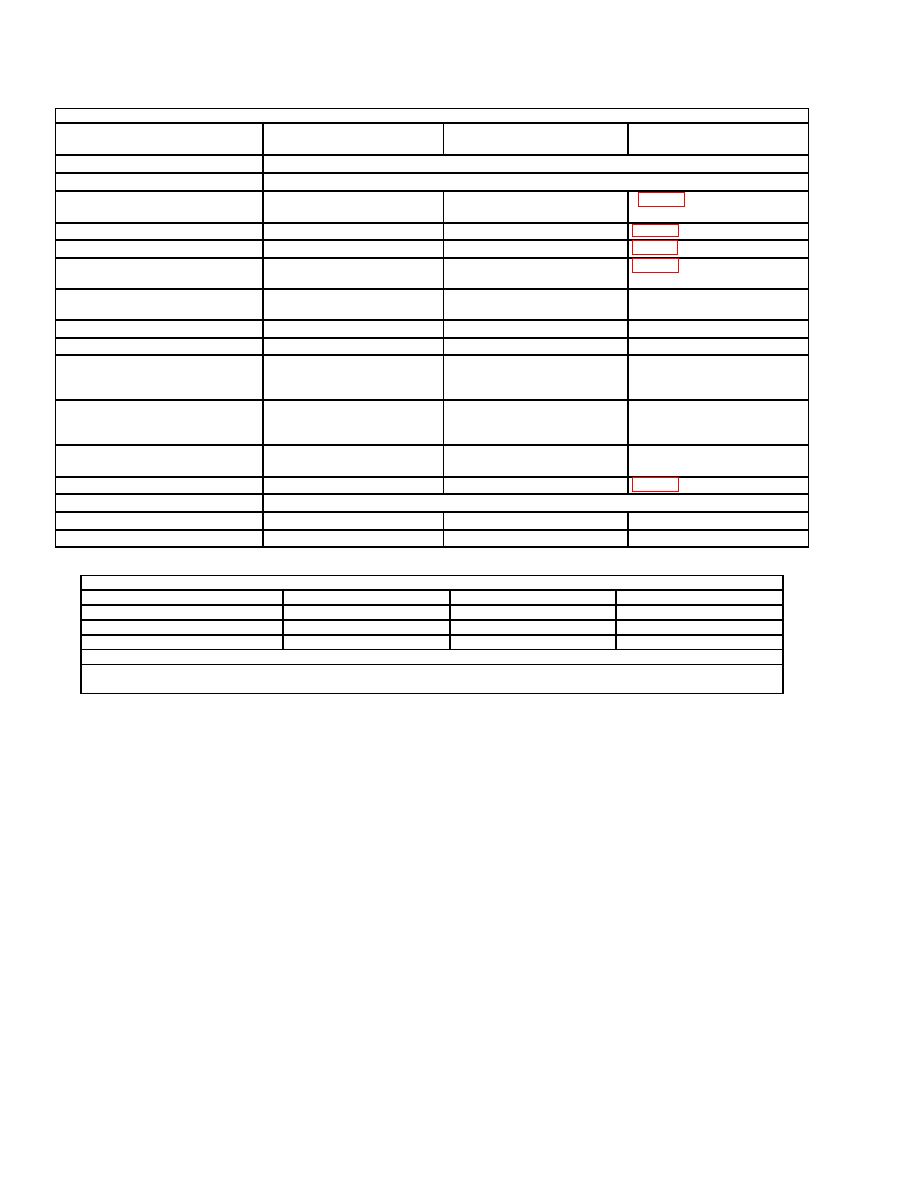

Description

Inspection

NSN

Application

Gage, ring

Projectile

IRI, RI, PI, UBLI

Gage, profile and alignment

Complete cartridge

5220-00-231-7775

IRI

Note 1. Ring gaging required only if round fails profile and alignment gaging.

Note 2. Profile and alignment gaging required only if not accomplished during IRI, or if round is visibly damaged.

(Profile andalignment gaging is required only one time during life cycle of lot.)

Previous Page

Previous Page