SB 742-1

Description

NSN

Application

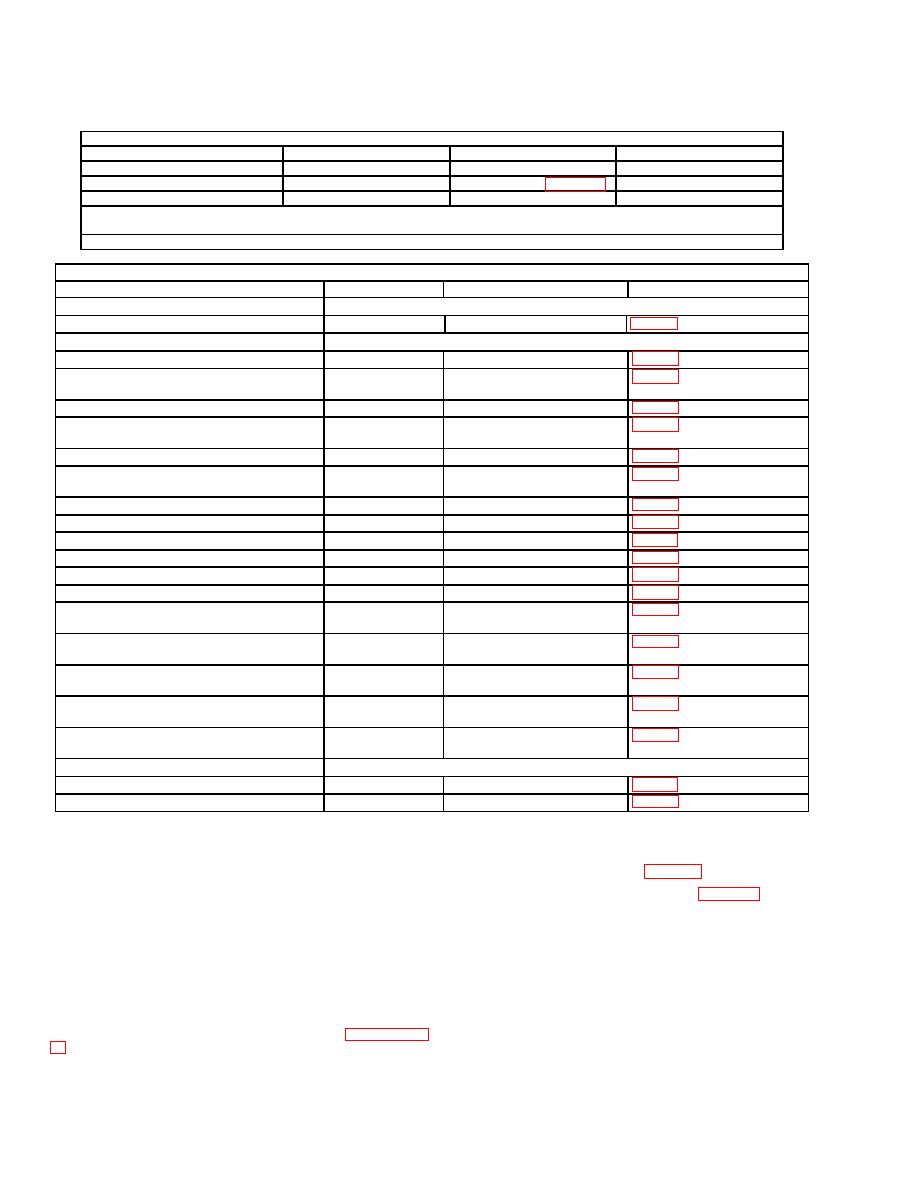

Inspection

Gage, profile and alignment

5220-00-231-2775

Complete cartridge

IRI,RI,PI,UBLI

Proportional counter

As specified in para J-7

IRI,RI,PI,UBLI

Swipe, Cloth, Test

Swipe Test

IRI,RI,PI,UBLI (NOTE 2

Note 1. Profile and alignment gaging required only if not accomplished during IRI, or if round is visibly damaged.

(Profile andalignment gaging is required only one time during life cycle of lot.)

Note 2. Swipe (smear) test will only be performed on damaged and/or corroded projectiles.

Classification

Application

Inspection Method

Inspection Description

1. Critical:

a. Projectile loose in cartridge case (M900)

Visual/manual

Para J-6i(4)

2. Major:

a. Windshield or windshield tip bent or damaged

Visual

b. Windshield loose (lateral or longitudinal

Visual/Manual

looseness only)

c. Bourrelet cracked or loose

Visual/Manual

d. Missing parts (e.g., bourrelet, obturator,

Visual

windshield tip bourrelet screws)

e. Corrosion on projectile parts (pitting)

Visual

f. Corrosion of primer as specified by TM 9-1300-

Visual

Para J-6a & J-6c

251-20

g. Yellow/yellowish white projectile corrosion

Visual/Swipe

Para J-6a & J-6d

h. Failure of cartridge to gage

Gage

Para J-6a & J-6e

i. Damaged inner or outer container

Visual

Para J-6a & J-6f

j. Hose clamp(s) not removed from sabot

Visual

k. Primer or igniter above flush

Straightedge

Para J-6a & J-6g

l. Primer staking missing

Visual

Para J-6a & J-6h

m. Obturating band damaged (e.g., cracked,

Visual/Gage

broken, or gouged).

n. Sabot damaged (e.g., cracked, broken, or

Visual/Manual

gouged)

o. Lateral movement of projectile (M774 and

Visual/Manual

Para J-6a & J-6I

M833)

p. Rust, metal tears or cracks in cartridge case

Visual

(M833 and M900)

q. Damage to cartridge which may expose DU

Visual/Swipe

Para J-6a & J-6d

core

3. Minor:

a. Damaged inner or outer container

Visual/Manual

Para J-6b & J-6f

b. Protective windshield cushion missing

Visual

gaps, windshield interfaces or if physical damage to projectile

is noted which could expose DU core.

a. Cartridges having any major defects will be reported

e. Perform gaging according to table J-1.

according to DA PAM 738-750, regardless of dollar value.

Defective quantities that are authorized for repair or

f. Inspect packing material according to chapter 2.

demilitarization will be transferred as directed by HQ, JMC, to

g. Testing to date has not shown electric primer assembled

a facility licensed to perform these procedures.

to these cartridges to be sensitive to initiation from mechanical

b. Replacement containers and protective windshield impact. Primers or igniters above flush are therefore to be

cushion should be requisitioned as required according to the considered major defects rather than critical. (Any straight

edge rule is suitable for checking this characteristic.)

procedures in applicable technical manuals.

c. Refer to paragraph

3-9,

TM

9-1300-251-20

for

h. Primers must be staked in two places, approximately

180 degrees apart. Stakes should show evidence of moving

inspection criteria.

cartridge case material into joint at cartridge case to primer.

d. Projectile will be swipe tested according to paragraph J- Stakes on primers with wrench holes will not necessarily

If there is no evidence of metal

Previous Page

Previous Page