SB 742-1

b. Gaging during these inspections (other than IRI) should

AMMUNITION CARTRIDGE, 75MM, BLANK M337

be limited to individual rounds showing evidence of damage or

SERIES

other conditions that may preclude loading or firing. Unless

the rounds requiring gaging are truly representative of the lot

being inspected, they should not be used to evaluate the lot.

Results, however, should be annotated on the DSR with the

a. DODIC: 1315-C025

reason for gaging.

b. Ammunition Type:

Cartridge, 75MM, Blank, M337

c. Table AD-1 identifies test and measurement equipment.

Series.

a. Inspection category:

category Y (three years), blank

No unique safety precautions are applicable to this item.

b. The sampling plan for inspection is according to

a. All IRI samples will be gaged using a profile and chapter 2.

alignment gage. Gaging is not normally required during RI, PI

or UBLI.

Item will be inspected according to chapter 2 and table AD-2.

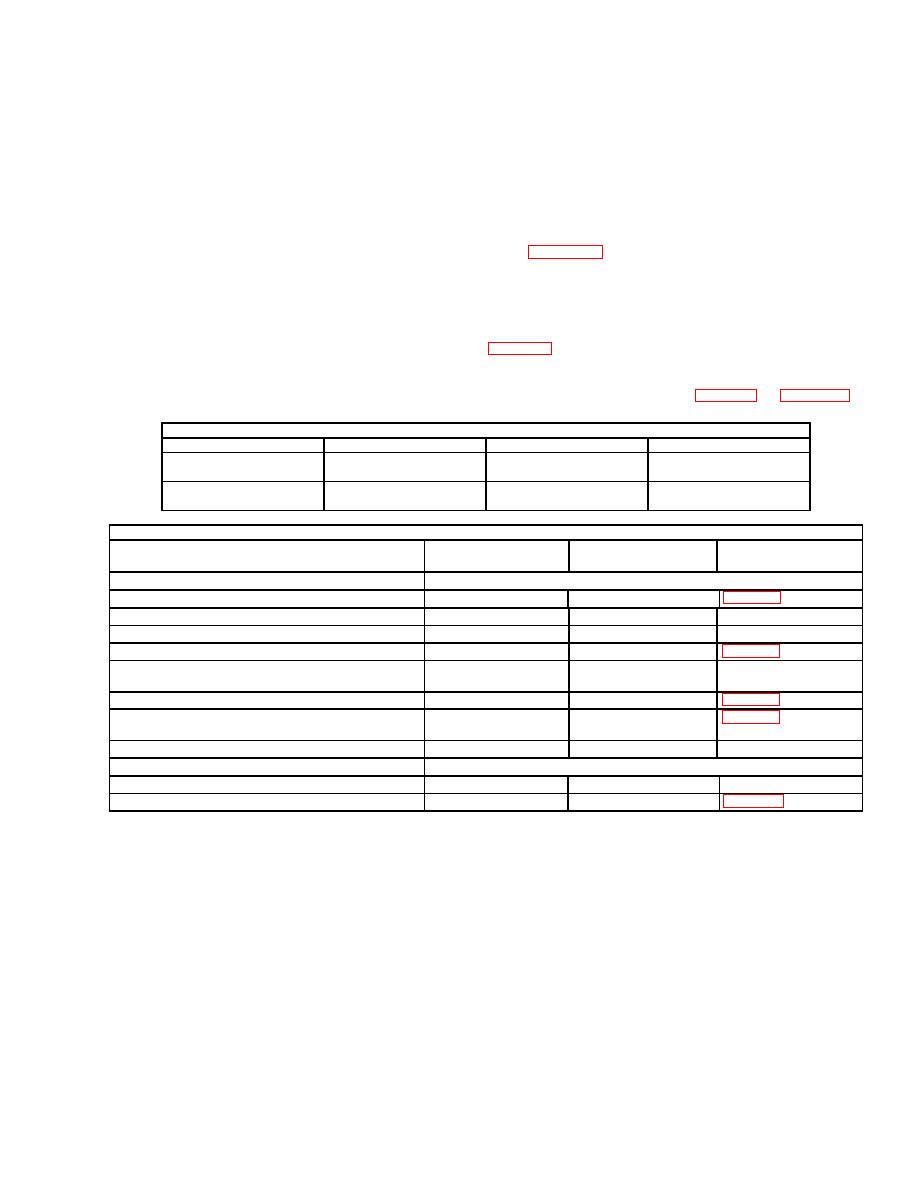

Description

NSN

Application

Inspection

Gage, profile and

Cartridge, M337A2

IRI, RI, PI, UBLI

alignment

Gage, profile and

Cartridge Brass case,

IRI, RI, PI, UBLI

alignment

M337A1

Classification

Application

Inspection

Inspection

Method

Description

1. Critical:

a. Primer above flush

All

Visual; Straight Edge

2. Major:

a. Primer loose

All

Visual/Manual

b. Closing Cup cracked, broken, punctured or malformed

All

Visual

c. Closing Cup Seal not continuous or groove not filled with

All

Visual

cement

d. Closing Cup Air escape hole not filled with cement

All

Visual

e. Cartridge case crack or split extending through sidewall or

All

Visual

bottom

f. Chamber gage failure

All

Gage

3. Minor:

a. Glue or asphalt on exterior of cartridge

All

Visual

b. Missing Protective Finish

M337A2

Visual

a. See drawing 7549273. Primer parts must not protrude

beyond rear face of cartridge case.

b. See drawing 7549273. Assure seal and air escape hole

are completely filled with resin cement. Any excess cement

should be removed from exterior of cartridge case.

c. Cracks or splits in cartridge case may expose black

powder filler to moisture that could cause accelerated

degradation of performance.

d. Gaging is required only during IRI or if visual inspection

is questionable.

e. See drawing 7549273.

Wax emulsion is required for

aluminum cartridge cases.

Previous Page

Previous Page