SB 742-1

(6) If using a continuous flow monitor and agent rocket reinstall sample port plug with serviceable gasket and

cannot be confirmed with an alternate method or no agent return item(s) to storage configuration and continue with SMI.

vapor is detected on last sampled rocket reinstall sample port

(8) (If agent is detected and then confirmed,

plug with serviceable gasket and return item(s) to storage

containerize leaking rocket(s) in approved overpack container,

configuration and continue with SMI.

apply required markings and place in approved storage

(7) When using a non-continuous monitor and agent location, IAW local procedures, and resume SMI. The decision

cannot be confirmed with alternate method, or no agent vapor to delay containerizing leakers will be based on ambient air

is detected on last sampled SFT, resample the previous set of contamination and the anticipated number of leakers in a

SFT's sampled. If no agent vapor is detected on last sampled structure. Movement of leakers to isolated storage may also be

delayed to consolidate movements.

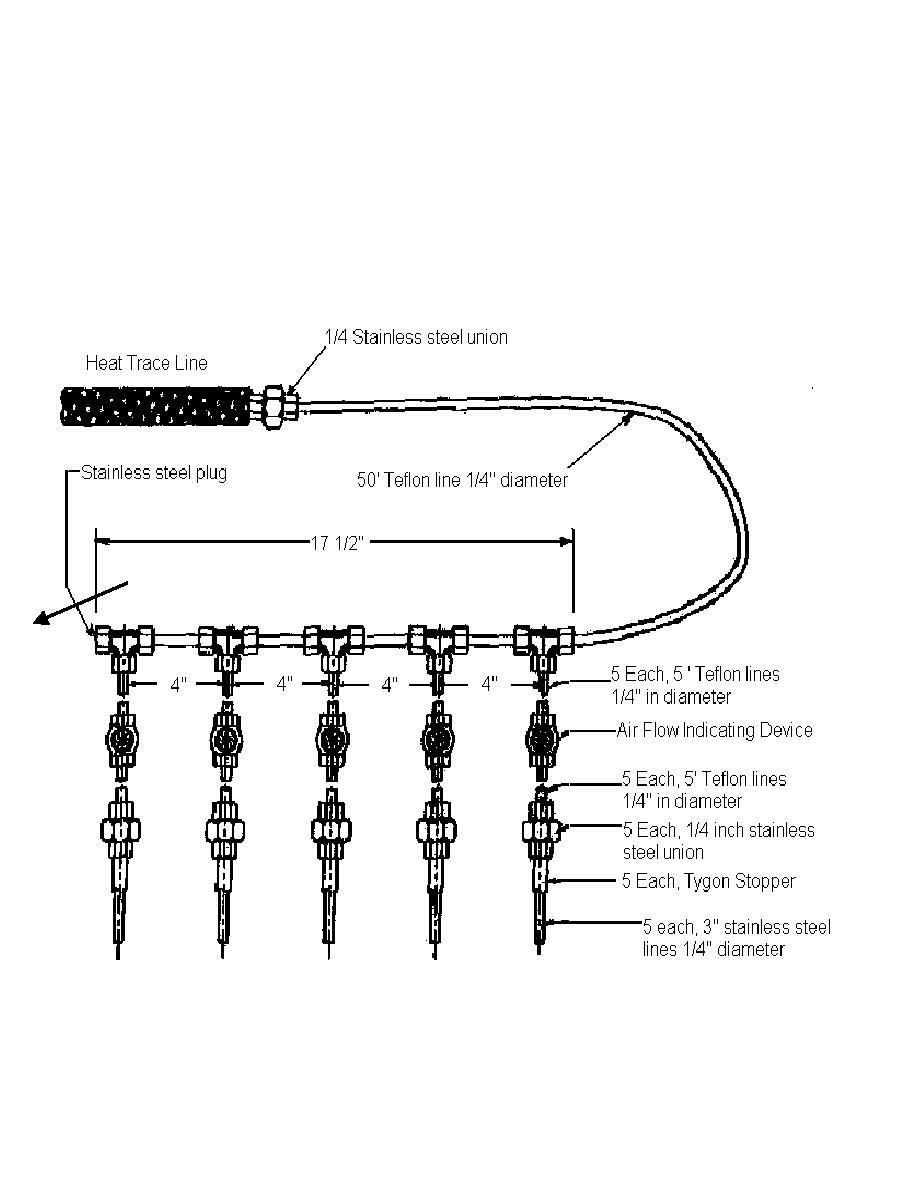

M55 ROCKET MANIFOLD

5 Each Stainless Steel T's

One end of approximately fifty feet of teflon line, inch in diameter, will be attached to the RTAP Heat Trace Line's inch stainless steel union. The

other end will be connected to a series of five (5) stainless steel "T"s using four (4) stainless steel tubes approximately three inches in length and inch in

diameter. The last "T" in the series will be closed off using a stainless steel plug. One teflon line, approximately five feet long and inch in diameter, will

be connected to each "T"s open orifice. Each five foot Teflon line will have an airflow indicator placed at the opposite end. Another 5 foot teflon line will

be connected to the air flow indicator and inch stainless steel union placed on the opposite end. These stainless steel unions will then have a stainless

steel line, three inches long and inch in diameter, connected to their open end. A piece of tygon tubing will be placed over each stainless steel line next to

the stainless steel union to prevent sample lines from being inserted into the SFTs sample port beyond the inch requirement.

Previous Page

Previous Page