SB 742-1

c. Leaking rockets will be reported IAW SB 742-1, chapter contain a known stable GB agent lot may be considered for re-

inclusion in Sample Plan A. Requests for re-inclusion will be

forwarded to the proponent of this SSI for approval.

b. When performing leaker isolation of M55, GB rockets,

a. Vapor test. Samples from each lot, will be tested for any intrusive monitoring can be credited toward the current

agent contamination inside the M441 SFT, see Table XX-1. quarter's sampling requirements. If the lot has already been

Sampling Plan A will be used for lots that have not experienced sampled for the current quarter, no credit can be taken. If a

leakers in their life cycle. Sampling Plan B will be used for lots leaker is encountered during the intrusive monitoring, the

that have experienced leakers, but have not been designated as remainder of the total sample size still must be completed for

leaker lots. Sampling Plan C will be used for those lots that this lot.

have been designated as Leaker Lots at your location. Lots in

Sampling Plan B that have not leaked in five or more years and

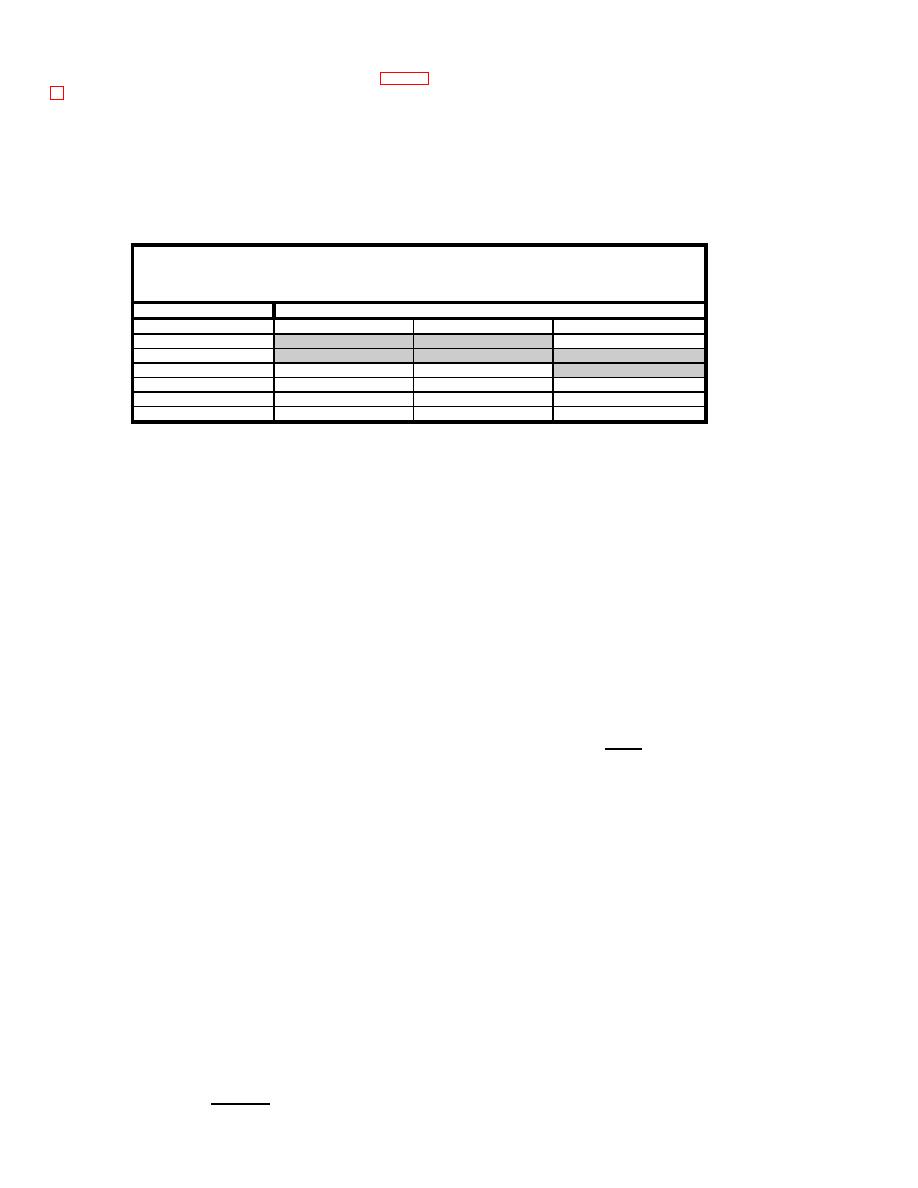

M55 GB Rocket Storage Monitoring Inspection

Sampling Plans

Lot Size

Quarterly (unless otherwise indicated) Sample Size

A

B

C

1

201

0-25

8

100%

161

441

252

26-150

402

151-300

6

16

301-750

9

23

64

751-3000

12

30

75

> 3000

15

35

85

Quantity indicated is to be sampled over a period of

In rare instances, the M441 SFT may develop

1

three years. This sampling may be accomplished at one

internal pressure during storage. Potential release

time within the three years or in increments as

of pressure associated with presence of liquid agent

determined by the QASAS-in-charge.

may result in expulsion of agent from sampling port

when plug is removed. Equal care should be taken

When total annual sample size exceeds the lot size, the

2

when

removing

either

end-sampling

plug.

lot will be sampled 100% each year.

This 100%

Situations have been experienced in which agent

sampling may be accomplished at one time within the

under pressure sprayed from one end of the firing

year or in increments as determined by the QASAS-in-

tube but not the other. Plug removal wrench must

charge.

be fitted with a splash shield.

When a rocket lot(s), or portion of a lot(s), has been

3

e. Remove sampling plugs from front and rear end cap's

scheduled for demilitarization within a designated

and examine for the presence of agent contamination. If

calendar quarter (three months), the lot(s), or portion of

contamination is suspected, test with M8 paper. Look inside of

lot(s), may be excluded from sampling during that

the sample port for evidence of solidified or crystallized agent,

quarter. If demilitarization has not commenced during

if present monitor from outside the sample port do not insert

the scheduled quarter (or is not imminent), sampling

sample probe.

shall resume in subsequent quarters. Further delays

are not authorized unless justified in writing by the

f. If front or rear end cap plug cannot be removed, and no

QASAS-in-charge, based upon changes in the

evidence of agent leakage is present, select a different sample.

demilitarization timeline. Sample sizes need not be

NOTE

increased in ensuing quarters to account for rockets

that were not sampled in a quarter during which a lot

With time, M441 SFTs have a tendency to settle

was scheduled for demilitarization

within the pallet that causes the end caps of the

SFTs to become misaligned with the openings in the

end boards of the pallets.

It is permissible to

remove the end boards from the pallet. It is not

a. Visually inspect all accessible M441 Shipping and

necessary to replace the end boards when the

Firing Tubes (SFT) in the structure for evidence of leakage and

operation is completed. However, they must be

general condition. Inspect for stability of stacks, condition of

retained so that they may be reconfigured to the

pallets and any other condition that could affect suitability for

pallet prior to intra-depot movement.

continued safe storage pending demilitarization.

Visual

inspections should be performed only to the extent possible

g. In the event damaged sampling port threads are noted,

without rewarehousing.

a thread chaser may be used or a self-tapping screw will be

installed as a replacement for the plug that was just removed.

b. Identify M55 rocket lot selected for sampling.

If either plug cannot be reinstalled the rocket must be

c. Identify individual rockets designated for testing. Those containerized in an SRC and tagged as a non-leaking rocket,

rockets that have been previously inspected should have been missing sample plugs.

tagged as such.

d. Verify that sampling plug in the front, end cap of the

SFT is in the 12 o'clock position. If sampling plug is not in the

a. The monitoring program described in the following

proper position, rotate M441 SFT until correct orientation is section is based upon the ability of the equipment to detect the

obtained. If M441 SFT cannot be rotated, check the position of presence of 0.5ng of GB in the collected air sample. A mass of

the aft end, sampling plug. The sampling plug closest to the 0.5ng of GB will be the action level for this program.

12 o'clock position will be removed first.

b. Gross level testing to prevent saturation of the low-level

CAUTION

detector separation column is optional. Maintain a inch

separation distance between the front-end sample port and the

Previous Page

Previous Page